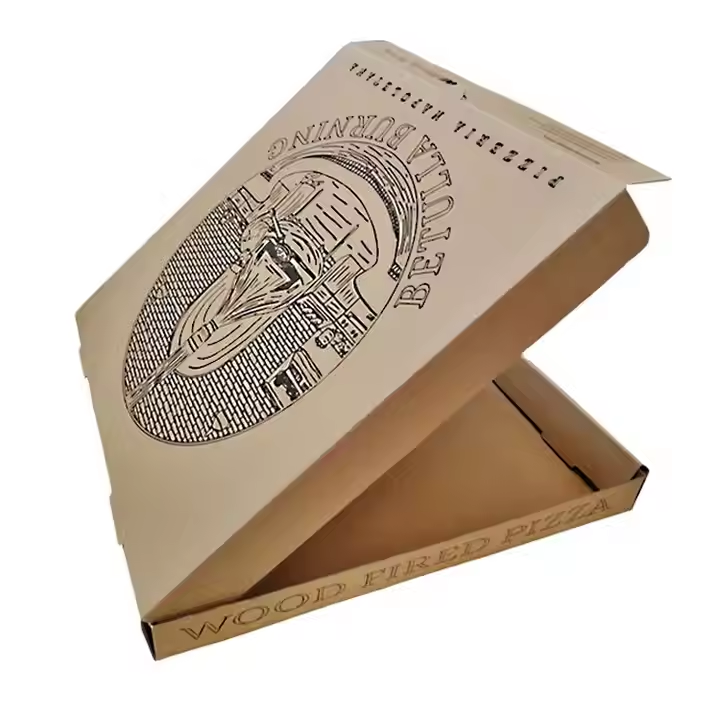

5 ply corrugated box

The 5 ply corrugated box represents a sophisticated packaging solution engineered to deliver exceptional protection and durability for various shipping and storage needs. This advanced corrugated structure consists of five distinct layers, incorporating three fluted mediums sandwiched between four flat liner boards, creating a robust multi-wall configuration that significantly outperforms standard single and double wall alternatives. The technological architecture of the 5 ply corrugated box utilizes alternating flute directions, typically combining different flute profiles such as BC, AB, or EB combinations to optimize strength characteristics and compression resistance. This innovative construction method distributes stress forces evenly across the entire surface area, preventing localized failure points that commonly occur in simpler packaging materials. Manufacturing processes employ high-grade recycled and virgin fiber materials, bonded with environmentally conscious adhesives that maintain structural integrity under varying temperature and humidity conditions. The primary functions of the 5 ply corrugated box encompass heavy-duty shipping applications, long-term storage solutions, and specialized industrial packaging requirements where standard boxes prove inadequate. Industries requiring superior protection for valuable merchandise, fragile electronics, automotive components, and bulk commodities rely heavily on this advanced packaging technology. The enhanced cushioning properties inherent in the multi-layer design effectively absorb impact forces during transportation, reducing product damage rates and associated costs. Edge crush strength ratings typically exceed 275 pounds per square inch, while burst strength measurements often surpass 650 pounds per square inch, demonstrating the exceptional structural capabilities of these premium packaging solutions. Temperature resistance characteristics allow the 5 ply corrugated box to maintain dimensional stability across extreme environmental conditions, making it suitable for international shipping routes and diverse climate zones.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY