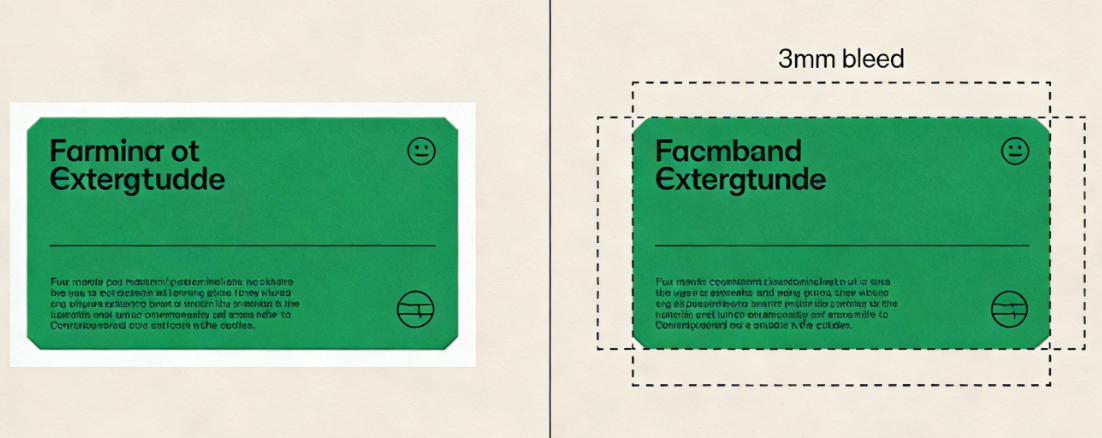

In custom packaging, to avoid white borders or the cutting off of key content, two important elements are considered during printing and layout: bleed and safety margin.

Bleed refers to the portion extending outwards from the final cut position, typically 3 millimeters (0.125 inches). This ensures that even minor cutting deviations won't result in white borders on the finished product, significantly impacting the brand's aesthetics. Safety margin, on the other hand, is a buffer area extending inwards from the final cut position. It places all important content, elements, and graphics within this area, ensuring that all information within the safety margin is printed intact without being cut off, thus avoiding high rework costs.

Both bleed and safety margin are crucial because they prevent edge misalignment or the cutting off of important elements, reducing the risk of reprints and ensuring brand consistency. Furthermore, clean, crisp cut edges provide customers with a better unboxing experience.

In short: Bleed = Avoid white borders; Safety margin = Avoid content being cut off. Mastering these two elements will allow you to achieve clean, precise cuts in your packaging, giving your brand a more professional image in the global market.

Contact Jinayon for your packaging design cut lines.

FAQ

What is the purpose of bleed in packaging design files?

Bleed extends background colors or images 3mm beyond the final cut line to ensure no white edges appear if the cutting shifts slightly during production.

How do safety margins protect my packaging design?

Safety margins keep all critical text, logos, and graphics safely inside a protected zone (usually 3–5mm from the cut line), preventing them from being trimmed off accidentally.

What happens if I forget to include bleed in my file?

Without bleed, even minor cutting inaccuracies can leave thin white borders along the edges of your packaging, requiring costly reprints to fix.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY