Material Efficiency in Folding Box Manufacturing

Lightweight Design Reducing Raw Material Consumption

The implementation of lightweight designs in folding boxes has significantly reduced the consumption of raw materials, leading to substantial cost savings in manufacturing. By employing innovative materials and engineering strategies, producers can achieve lighter box constructions that maintain the necessary strength and durability. For example, advancements in material science have enabled the development of stronger, lighter materials, making it possible to use less raw material per unit. This not only cuts down on costs but also aligns with eco-friendly practices, appealing to conscious consumers. According to industry reports, embracing lightweight designs can lead to cost savings of up to 15%, thus offering a compelling financial incentive for manufacturers.

Automated Production Lines for Faster Turnaround

Automation in folding box manufacturing plays a pivotal role in enhancing production speed and efficiency. The integration of technologies such as robotic assembly systems streamlines the entire production process, ensuring faster turnaround times compared to traditional methods. These automated systems can perform tasks like cutting, folding, and gluing with high precision, significantly reducing the margin for human error. Statistics show that automation can reduce production time by up to 30%, enabling manufacturers to meet rising demands more effectively. As a result, the adoption of automated production lines is becoming a competitive necessity in the folding box manufacturing industry.

Logistics Optimization Through Space-Saving Designs

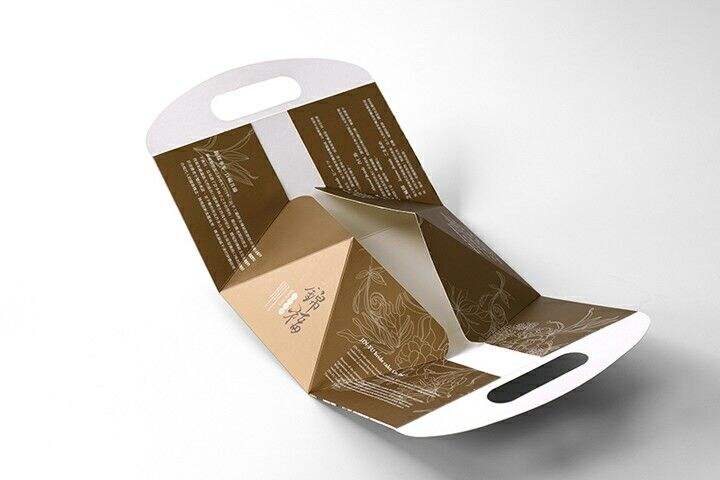

Flat-Pack Configuration for Efficient Transportation

Flat-pack configurations revolutionize the transportation of goods by significantly reducing the volume of space required during transit. This optimization translates into substantial cost savings as businesses can transport more units in fewer trips, reducing fuel consumption and overall expenses. Reports from industry leaders indicate a noticeable decrease in shipping costs—up to 30%—after adopting flat-pack solutions. For instance, a prominent furniture company that switched to flat-pack designs reported a 25% reduction in logistics costs, enhancing their profit margins and supply chain efficiency.

Warehouse Stackability Advantages

The stackability of folding boxes plays a crucial role in maximizing warehouse space utilization. By designing boxes with uniform dimensions and robust construction, businesses can efficiently stack more units without risking structural compromise, leading to significant space savings. This design feature allows companies to increase their inventory without needing additional storage facilities. According to a warehouse management study, the adoption of stackable folding boxes resulted in up to 40% more products stored in the same space. This not only optimizes warehousing costs but also improves order fulfillment processes by enhancing accessibility and inventory management.

Sustainability Drivers in Modern Supply Chains

Recyclable Materials Meeting Circular Economy Demands

Utilizing recyclable materials in the manufacturing of folding boxes is crucial for aligning with the circular economy's principles. This approach not only minimizes waste but promotes the reuse of materials, thereby reducing the environmental impact of packaging industries. Statistics indicate that over 75% of paper and cardboard-based packaging is recycled annually, making it a highly sustainable option compared to other materials. Certifications such as FSC (Forest Stewardship Council) and standards from organizations like the Sustainable Packaging Coalition endorse these recyclable materials, ensuring they meet stringent environmental criteria. By prioritizing the use of recyclable materials, companies can notably enhance their commitment to sustainability, meet consumer demands for eco-friendly products, and contribute positively to environmental conservation.

Regulatory Compliance Across Global Markets

Navigating the complex landscape of global packaging regulations is a significant challenge and opportunity for companies. Different countries enforce various standards that impact the design and production of folding boxes. For instance, the European Union has strict guidelines under the EU Packaging Waste Directive, which requires companies to focus on recycling and reducing packaging waste. Compliance with such regulations not only involves adhering to specific material and labeling requirements but also dictates certain design alterations to meet safety and environmental standards. Companies like Mondi Group demonstrate effective navigation through such regulatory challenges by integrating sustainable solutions and achieving certifications like the WorldStar Awards. By aligning packaging strategies with global regulations, businesses not only ensure legal compliance but also strengthen their market position by fostering trust and meeting international sustainability expectations.

E-Commerce Revolution and Packaging Requirements

Damage Prevention in Last-Mile Delivery

Packaging is crucial in ensuring products arrive undamaged during the last-mile phase. The last-mile delivery, the final leg of the shipping journey, poses unique challenges due to potential rough handling and environmental factors. Innovations like cushioning materials and secure sealing techniques have become indispensable in minimizing these risks. A report by Statista highlighted that damages in e-commerce deliveries can be significantly high, with up to 11% of packages experiencing damage during transit. By adopting robust packaging solutions, these rates can be reduced, enhancing consumer satisfaction and loyalty.

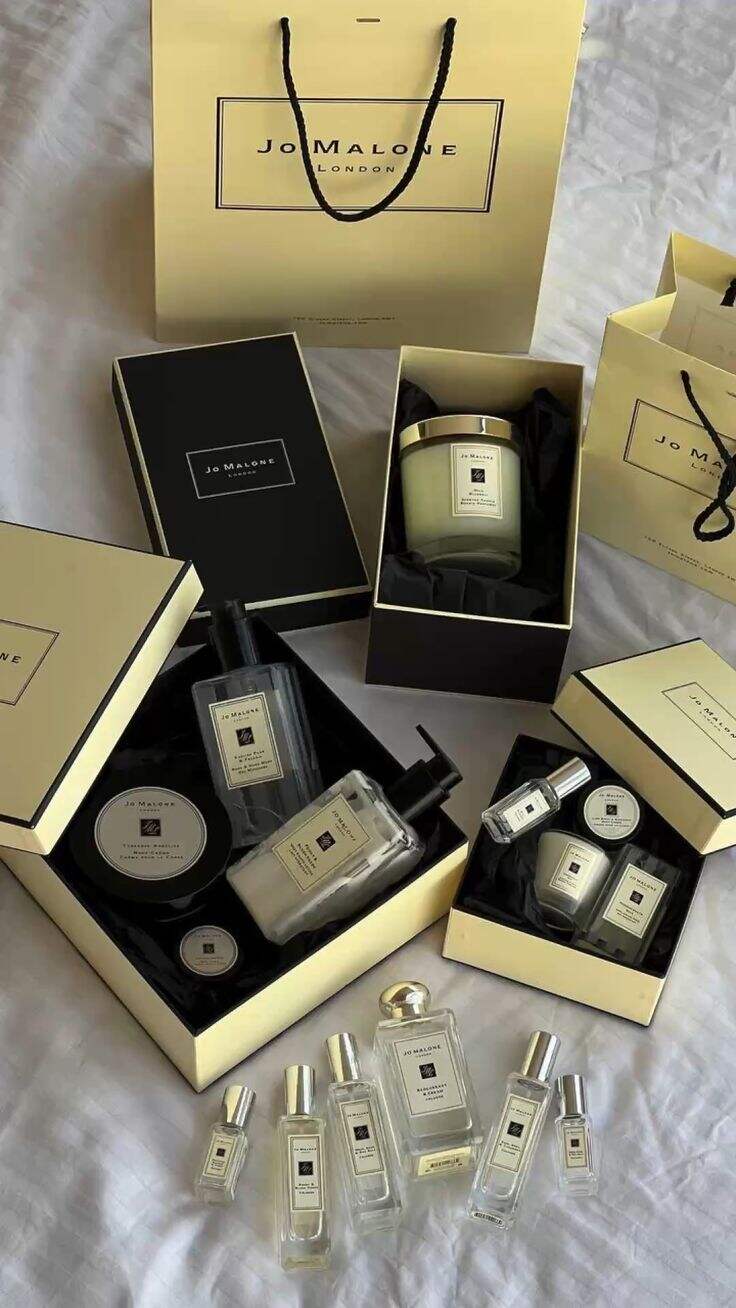

Brand Differentiation Through Custom Printing

Custom printing on folding boxes has a significant impact on brand identity and recognition. It allows brands to create unique packaging that stands out in a crowded marketplace, enhancing the product's appeal on a retail shelf. Variable data printing offers flexibility for personalization, allowing brands to tailor messages or designs for specific audiences, thus opening new marketing opportunities. For example, Coca-Cola's “Share a Coke” campaign used personalized printing effectively, leading to a notable increase in sales. By leveraging customized packaging, brands can reinforce their identity and engage consumers on a more personal level.

Smart Packaging Integration and Future Trends

Track-and-Trace Technology Implementation

Track-and-trace technology has become a pivotal component in enhancing supply chain transparency, particularly through folding boxes. By integrating technologies such as QR codes and RFID tags, businesses can significantly boost product tracking and inventory management. These tools offer real-time data on product location, helping businesses manage stocks more effectively and ensuring timely deliveries. According to recent studies, companies that have adopted these technologies reported a notable reduction in inventory losses, showcasing their importance in maintaining operational efficiency and transparency within the supply chain.

Biodegradable Coatings for Enhanced Sustainability

Adopting biodegradable coatings on folding boxes presents considerable environmental benefits by minimizing ecological impact. These coatings, often made from materials like starch, cellulose, or lactic acid, offer sustainable alternatives compared to traditional options, without compromising performance. The industry trends show a growing preference for biodegradable coatings as they align with global sustainability goals. A study published in the Journal of Cleaner Production highlights how these coatings are equally durable, paving the way for their widespread adoption as businesses strive to reduce their carbon footprint.

These advancements not only support environmental goals but also enhance the marketability of folding boxes, encouraging businesses to integrate smart and eco-friendly practices into their packaging solutions.

FAQs

What are the benefits of lightweight folding box designs?

Lightweight designs reduce raw material consumption, leading to cost savings, and align with eco-friendly practices.

How does automation improve folding box manufacturing?

Automation enhances production speed and precision, reduces human errors, and allows for faster turnaround times.

How do flat-pack configurations impact transportation costs?

They significantly reduce the space required for transit, leading to cost savings by allowing more units to be transported in fewer trips.

Why are stackable folding boxes beneficial in warehouses?

They maximize space utilization, allowing more inventory without the need for additional storage facilities.

What role do recyclable materials play in sustainability?

Recyclable materials minimize waste, supporting circular economy principles and reducing environmental impact.

Why is regulatory compliance important in folding box manufacturing?

Compliance ensures adherence to global standards, promoting safety and environmental sustainability, and strengthens market trust.

How do custom printing options enhance brand identity?

Custom printing creates unique packaging that boosts brand recognition and personalization for targeted marketing.

Table of Contents

- Material Efficiency in Folding Box Manufacturing

- Logistics Optimization Through Space-Saving Designs

- Sustainability Drivers in Modern Supply Chains

- E-Commerce Revolution and Packaging Requirements

- Smart Packaging Integration and Future Trends

-

FAQs

- What are the benefits of lightweight folding box designs?

- How does automation improve folding box manufacturing?

- How do flat-pack configurations impact transportation costs?

- Why are stackable folding boxes beneficial in warehouses?

- What role do recyclable materials play in sustainability?

- Why is regulatory compliance important in folding box manufacturing?

- How do custom printing options enhance brand identity?

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY