Introduction

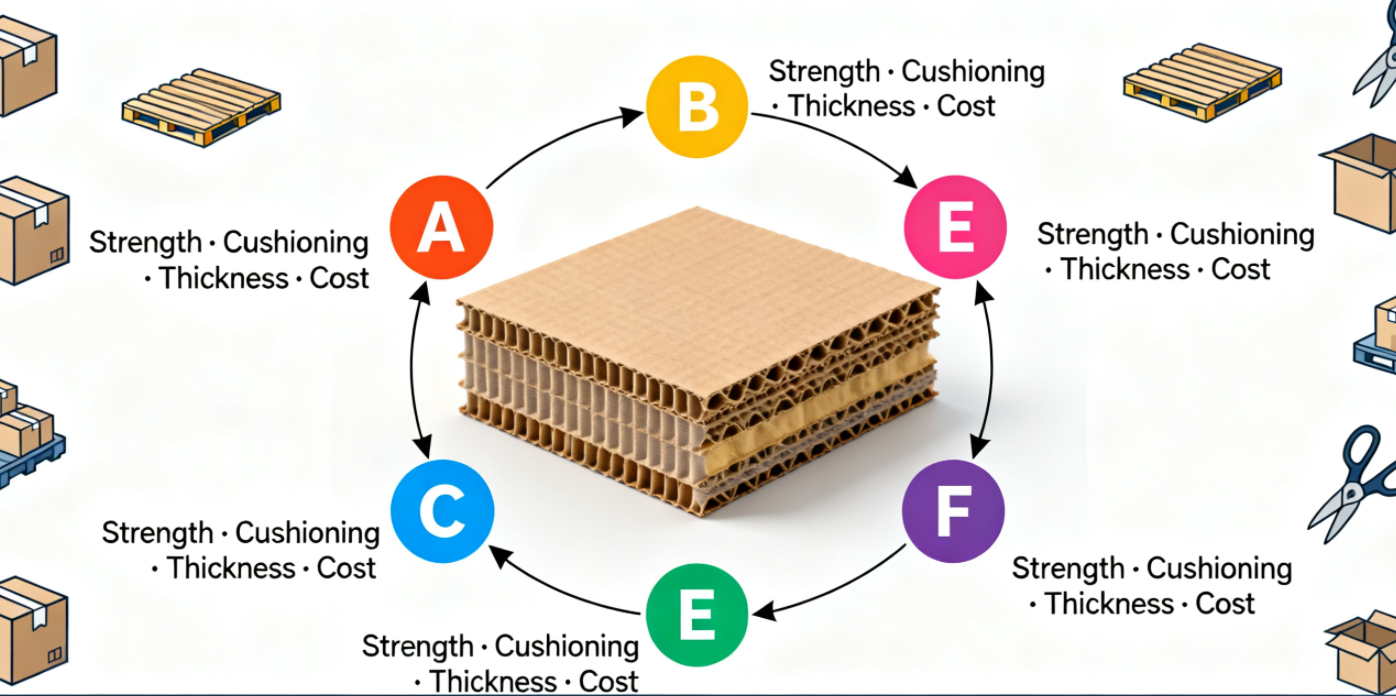

Corrugated boxes are widely used in the packaging industry. The performance of a box primarily depends on the corrugation, the corrugated core paper sandwiched between the linerboards. It determines the box's strength, cushioning performance, thickness, and cost. Currently, there are five common corrugated types: A-flute, B-flute, C-flute, E-flute, and F-flute. Each type is suitable for different applications, and choosing the appropriate corrugated type directly affects the product's protective effect and cost-effectiveness. Therefore, this guide will analyze each corrugated box type in detail to help you choose the best corrugated type based on your product's needs.

Introduction to Different Corrugations

Before choosing a corrugated type, we need to understand that there is no universal "best" corrugated type; there are only optimal corrugated types for different applications. Therefore, to make an informed choice, it is essential to first understand these five main corrugated types.

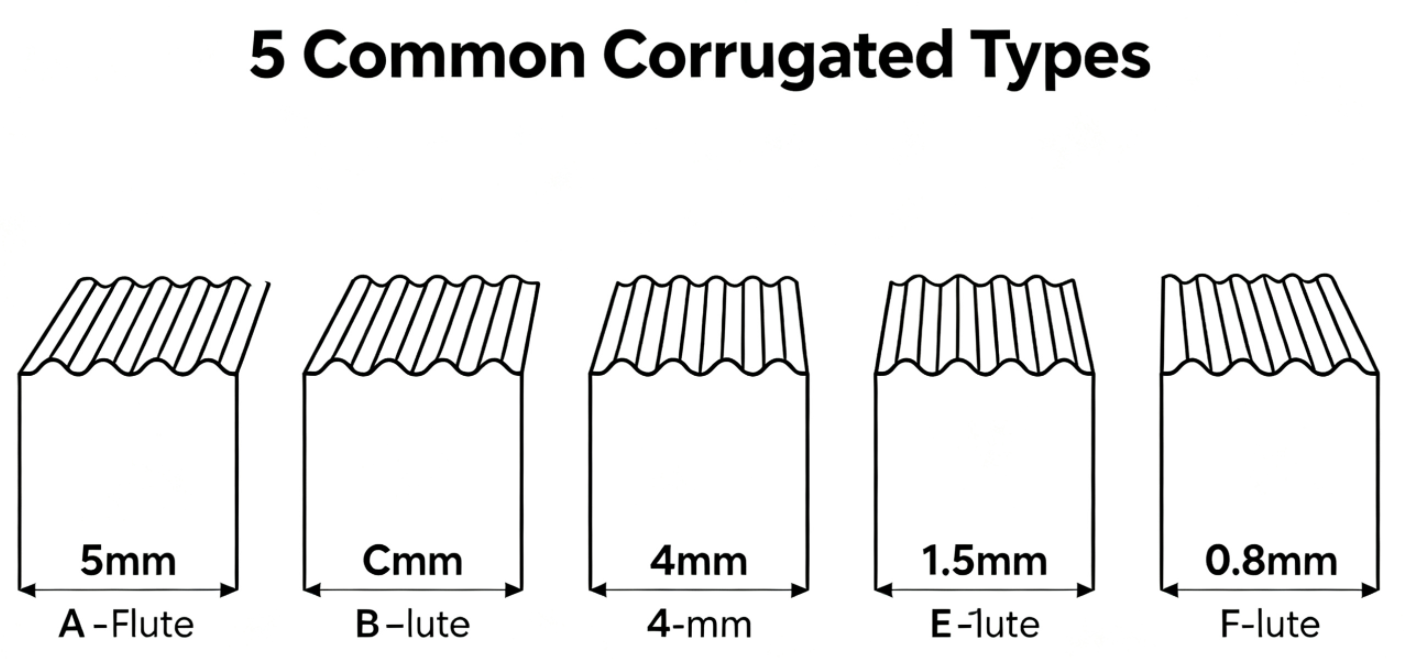

A-flute

Thickness: Approximately 5mm

Characteristics: The most basic corrugated type and also the thickest among common types. It has excellent buffering and shock-absorbing properties, making it an ideal container for large items (such as household appliances, furniture, etc.), fragile items and precision items, etc. However, its size is relatively bulky and it occupies a large amount of space.

Most suitable for: Fragile items, large items, heavy items

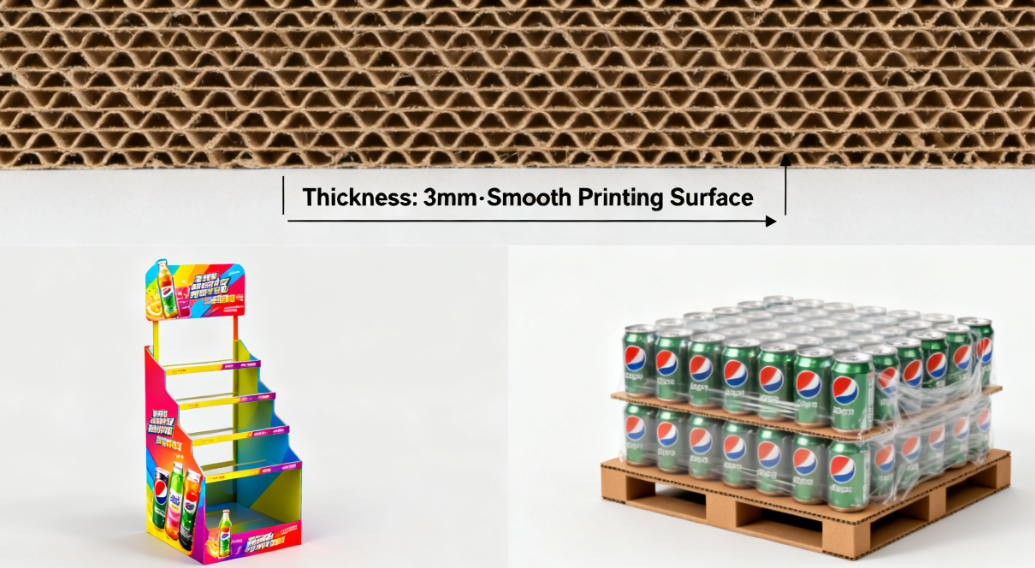

B-flute

Thickness: Approx. 3mm

Characteristics: Excellent cushioning performance; its smooth surface also allows for printing.

Most suitable for::Inner packaging, die-cut display racks, canned beverages, and shrink-wrapped pallets.

C-flute

Thickness: Approx. 4mm

Characteristics: C corrugated board combines the cushioning of A corrugated board with the smoothness of B corrugated board, resulting in good cushioning and printing performance. It is the most common corrugated board type in the corrugated industry.

Most suitable for: General shipping boxes, various consumer goods, and combination packaging.

E-flute

Thickness: Approx. 1.5mm

Characteristics: Lightweight and thin with high corrugation density, suitable for protecting small items. E corrugated boards are easy to fold, store, and transport, taking up little space, and are therefore widely used in product packaging.

Most suitable for: Retail ready-to-use packaging, cosmetic boxes, pizza boxes, consumer goods cartons, and any occasion requiring high-end printing effects.

F-flute

Thickness: Approx. 0.8mm

Characteristics: The thinnest and most compact corrugated board. Although its cushioning performance is weaker, it provides excellent protection for small, fragile items. Therefore, F-flute corrugated board is often used for the inner packaging of small retail goods such as perfume boxes and jewelry boxes, which emphasize a minimalist and high-end feel.

Most suitable for: High-end product packaging, small electronic products, jewelry boxes, perfume boxes, etc.

Corrugated Board Performance Comparison Table

| Performance indicators | Buffering / Impact Resistance | Compressive strength / Stack strength | Resistant to puncture | Printability | Thickness (mm) | Space utilization rate | Weight | Cost-effectiveness |

| A-flute | Excellent (Optimal) | Good | Generally | Generally | 5mm | Poor | Heavier | Medium |

| B-flute | Poor | Excellent (Optimal) | Excellent | Excellent (Optimal) | 3mm | Very good | Medium | Good |

| C-flute | Very good | Very good | Good | Good | 4mm | Good | Medium-Heavier | Excellent (Optimal) |

| E-flute | Generally | Good | Very good | Very good | 1.5mm | Excellent | Lighter | Medium-Higher |

| F-flute | Poor | Generally | good | Excellent | 0.8mm | Excellent (Optimal) | Extremely light | Higher |

Conclusion

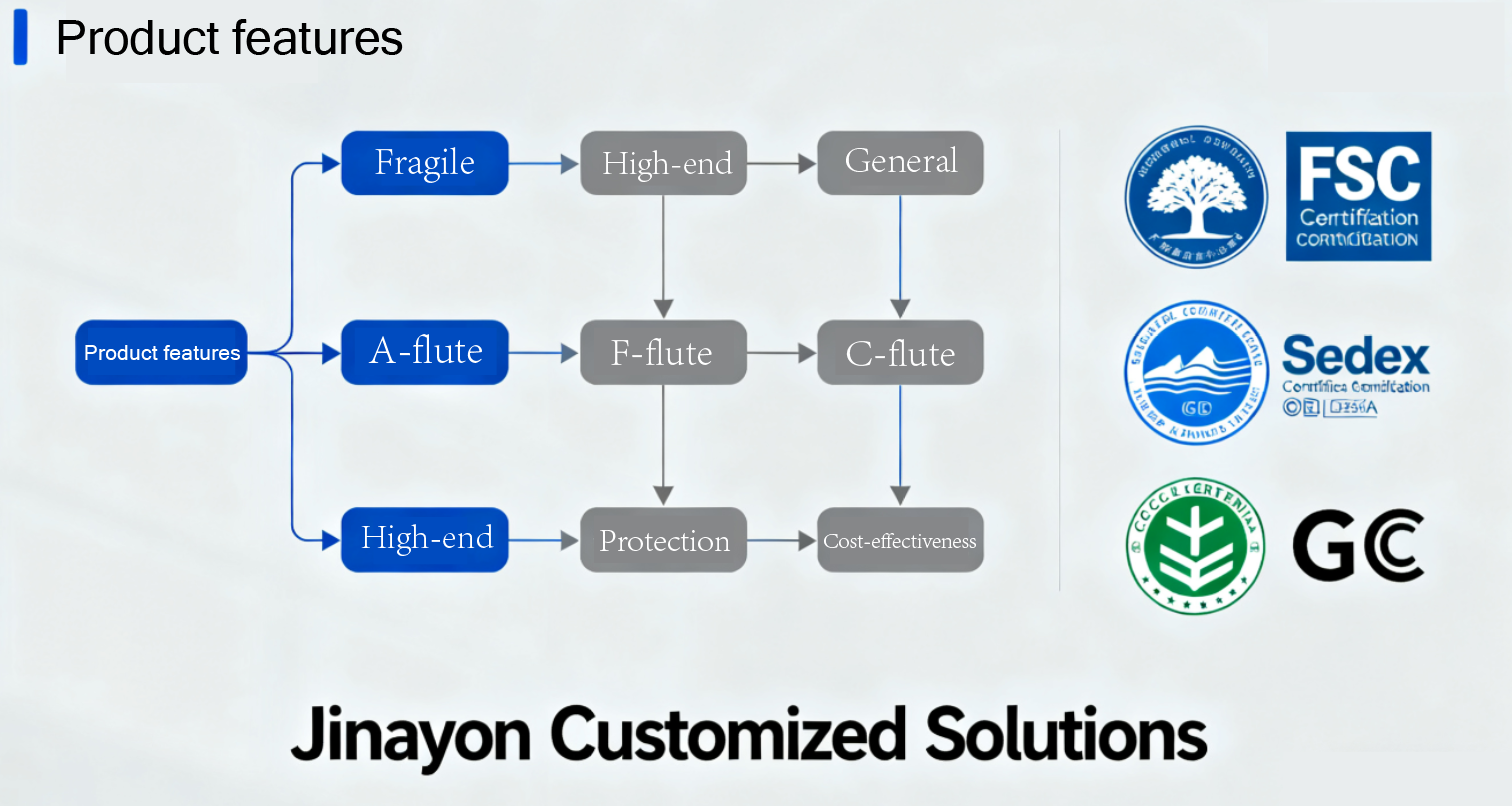

Choosing the right corrugated board is not just about strength; it's about matching packaging performance with product characteristics, brand positioning, and logistics strategy. Remember: there is no "one-size-fits-all" corrugated board—C-flute is suitable for most general applications, but specific products require targeted selection, such as A-flute for fragile items, B-flute for heavy-duty items, and F-flute for high-end products.

Jinayon helps global clients make these decisions every day, providing comprehensive customized corrugated board solutions from sturdy export boxes to elegant unpacking experiences. With multiple international certifications including FSC, Sedex, and GCC, Jinayon ensures your packaging is not only powerful but also compliant, environmentally friendly, and trustworthy.

Contact Jinayon to obtain a one-stop corrugated box solution.

FAQ

Which corrugated flute offers the best protection for heavy or fragile items during international shipping?

.For heavy or fragile items, A-Flute (5mm) is typically the best choice. It provides the highest level of cushioning and shock absorption due to its thick structure, making it ideal for protecting household appliances, furniture, and other precision items during long-distance transport.

We need boxes for retail displays that are both strong and have excellent print quality. What do you recommend?

We recommend B-Flute (3mm). It offers excellent compressive strength for stacking and good puncture resistance, while its smooth surface is perfectly suited for high-quality printing, making it a top choice for die-cut display racks and retail-ready packaging.

How does choosing the right flute type impact our overall packaging and logistics costs?

The flute choice directly impacts material costs, shipping weight, and storage space. Thicker flutes (A, C) may have higher material costs but prevent product damage. Thinner flutes (E, F) reduce shipping costs and warehouse space due to their lightweight and compact nature. The right choice optimizes total cost by balancing protection with operational efficiency.

Table of Contents

- Introduction

- Introduction to Different Corrugations

- C-flute

- Corrugated Board Performance Comparison Table

- Conclusion

-

FAQ

- Which corrugated flute offers the best protection for heavy or fragile items during international shipping?

- We need boxes for retail displays that are both strong and have excellent print quality. What do you recommend?

- How does choosing the right flute type impact our overall packaging and logistics costs?

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY