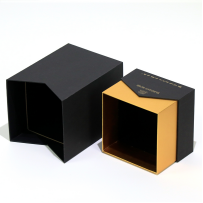

The Unique Structure of The Telescoping Box (Framed Lid and Base Box)

The global perfume industry is a vibrant arena, with Europe and the United States having a huge perfume market. The corresponding perfume packaging boxes are also very popular in various countries. Among many perfume packaging and, there is a very classic and exquisite packaging, which is the framed base and lid box. And you must be very curious about how such exquisite things are made, today we will find out. A framed lid and base box, also known as a "shoulder and neck rigid box," features a three-piece construction:

Base: The bottom box that holds the product.

Neck (or Inner Tray): A raised part attached to the base that extends upward, often visible or partially covered when closed.

Lid (Top Cover): The cover that fits over the base, usually stopping at the “shoulder” for a flush, refined finish.

Differences Compared to Standard Lid and Base Boxes

Visual Layering: The framed style provides an additional visual step (the shoulder), which creates a more premium and structured appearance.

Structural Integrity: It offers improved sturdiness and protection due to the three-layered design.

Unboxing Experience: The layered reveal enhances the luxury unboxing feel, ideal for upscale goods like perfumes or jewelry.

Customizable Neck Height: Tailor the visible shoulder part to match branding or aesthetic needs.

The Process that Attributes to its attractive Shape: Cutting Slot

In the packaging industry, V-grooving is a crucial process. The meaning of V-grooving is to cut a V-shaped groove on the cardboard. The cardboard will naturally bend and fold at these grooves, making the packaging box more vivid and three-dimensional, which can significantly enhance the three-dimensional sense of the packaging box. It gives the packaging box unique performance and charm, making it stand out among many packaging forms. This three-dimensional sense not only makes the packaging box more visually attractive but also adds a sense of dignity and uniqueness to the gift.When consumers pick up the packaging box, they can feel its unique texture and shape, which will generate higher expectations and a favorable impression of the gift inside.

The Selected material sets the tone for Modest Elegance

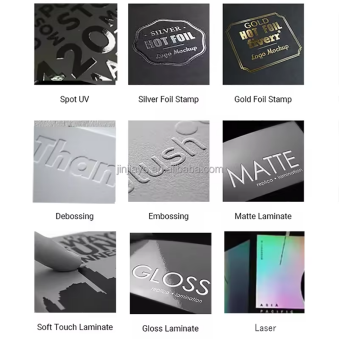

The material is made of coated paper mounted gray board, which is durable and not easy to deform. Coated paper has good strength, toughness and tear resistance, and the surface is very flat, which is suitable for printing design. Hua Keyi uses hot silver embossing, UV and other processes for the logo, which is simple and generous, and at the same time highlights the brand.

Well Designed Internal Lining Ensures a Safe and Sound Unboxing Experience.

Perfumes are mostly packed in fragile glass bottles, so it is particularly important to protect their safety during transportation. For this reason, we specially customize flocked EVA linings with excellent cushioning and protection properties for perfume bottles. They can be fixed in the lining and enhance the appearance. Since EVA is easily deformed under pressure, it is usually designed to be 2-3mm smaller than the inner diameter to avoid deformation, or reduce the thickness of the lining.

How to Customize your own perfume packaging

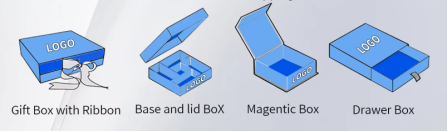

To create a custom perfume box is more than just design — it’s building a brand experience. Here are some steps that how you can develop the perfect box for your perfume. Each box style offers a different tactile and visual experience — choose what fits your product and audience.

Step 1:Box Style

Framed Base and Lid box

Popular options include:

Magnetic flap boxes

Drawer-style rigid boxes

Hinged lid boxes with ribbon closures

Step 2: Materials

Coated paper

Soft-touch paper

Textured paper

Foil paper

Step 3: Surface Finishing

Hot foil stamping for your logo

Spot UV to highlight patterns

Ribbon pulls or metallic inserts

Embossing or Debossing for the logo

Matte/glossy lamination to make it the scratch-proof

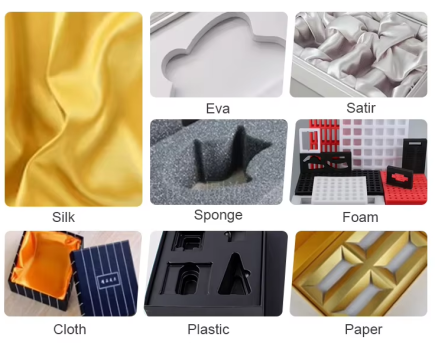

Step 4: Insert and Protect

EVA sponge

Velvet

satin-lined inserts

support your bottle securely while enhancing presentation.

At Jinayon, we offer end-to-end custom perfume packaging solutions — from design support to production, and global delivery.

Your fragrance deserves packaging that whispers luxury before a single spray.

FAQ

Q1: What’s special about a framed lid and base box?

Its three-layer design (base, neck, and lid) adds visual depth, improves durability, and creates a luxurious unboxing experience.

Q2: Why is V-grooving important?

It allows precise folding for sharp edges and 3D shapes, making the box look polished and high-end.

Q3: What materials are used for durability?

Coated paper on gray board ensures strength and smooth printing. Options like foil or textured paper add extra luxury.

Q4: How are fragile perfume bottles protected?

Custom flocked EVA linings hold bottles securely. They’re slightly smaller than the box to avoid deformation during shipping.

Q5: What customization options are available?

Choose from finishes (hot foil, UV gloss), materials (soft-touch, metallic), and styles (magnetic closure, drawer boxes).

Q6: Why choose this over simpler packaging?

It combines elegance (layered design), protection (sturdy build), and a premium unboxing feel to elevate your brand.

Q7: What’s the customization process?

Pick a box style, select materials, add finishes (like embossing), and choose protective inserts (EVA, velvet).

Q8: How does packaging reflect brand quality?

Premium materials and finishes (e.g., matte lamination, debossed logos) silently convey luxury before the bottle is seen.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY