When customizing packaging, we encounter two processes: Spot UV and glossy lamination. Both processes give packaging a mirror-like shine. But how do we differentiate them? This article will briefly introduce the two processes for quick distinction.

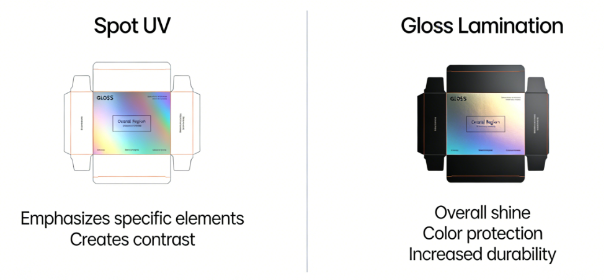

Spot UV involves precisely applying a transparent, glossy coating to specific areas of the packaging, such as patterns, text, and logos. Then, ultraviolet curing technology is used to cure the coating, creating a striking contrast between the UV-coated areas and the matte surface of the packaging, increasing depth and visual focus. Therefore, Spot UV is an ideal choice for packaging that emphasizes brand elements.

Glossy lamination involves covering the entire surface of the packaging with a glossy film, giving the entire package a reflective effect under light. It also enhances the saturation of printed colors and adds wear resistance.

Therefore, the choice depends primarily on your needs: if you prioritize a focused element, choose Spot UV; if you need overall brightening with some protection, choose glossy lamination. In an increasingly precise and competitive market environment, choosing the right packaging technology can enhance the customer's unboxing experience. Therefore, quickly understanding the differences between the two technologies is crucial for making the most suitable choice.

Contact Jinayon for a quick and customized one-stop packaging solution.

FAQ

Which option offers better protection for packaging?

Gloss lamination provides superior overall protection against scratches, moisture, and wear due to its full-coverage film. Spot UV adds limited durability only to coated areas but excels in creating tactile and visual focus points.

How do cost and production time compare between the two processes?

Gloss lamination is generally more cost-effective for large runs due to simpler application. Spot UV requires precise masking and UV curing, often increasing cost and time, but delivers unmatched design precision for luxury packaging.

Which finish is more environmentally friendly?

Both can be eco-friendly depending on materials. Water-based UV coatings and recyclable laminate films are available. For minimal impact, choose FSC-certified paper with solvent-free coatings and ensure laminates are separable for recycling.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY