Suppliers commonly suggest using anti-scratch film to prospective customers seeking manufacturing solutions for their products.

So, what is anti-scratch lamination? This article provides a clear and comprehensive overview.

1. Definition

Anti-scratch lamination is a transparent protective lamination. It can prevent the product from being damaged,

so it is different from the ordinary glossy lamination and matte lamination.

Anti-scratch lamination has a very scratch-resistant surface, which can protect the product during transportation.

For example, this drawer box from Jinayon employs the anti-scratch lamination technology.

The text and images on the product can remain intact and not be damaged.

2. How It Works

2.1 Composition

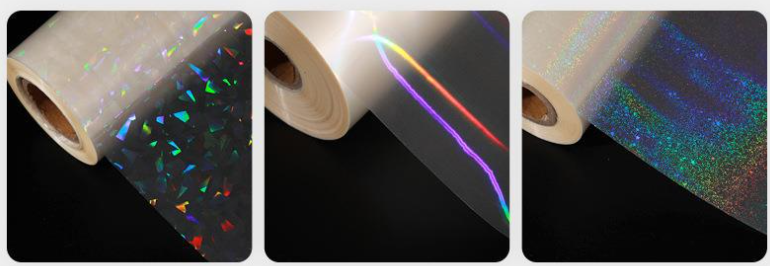

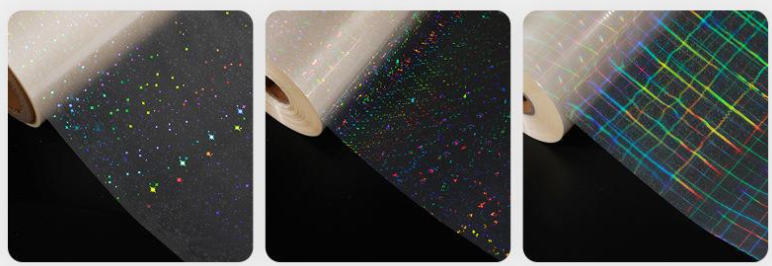

The anti-scratch film is usually made of ultra-thin sheets of polypropylene coated with tiny hard particles.

These particles are the key to the anti-scratch property, as they can resist most scratches.

2.2 Application

During the production process, by controlling the heat and pressure, this anti-scratch film is firmly adhered to the paper or cardboard.

And by exposing the surface to UV light for a short period of time, it can be made to solidify.

3. Benefits

3.1 Long-Lasting Beauty

The anti-scratch lamination can effectively protect the product, thereby extending its service life for a long time.

Therefore, this durability enables the long-term value of the product to increase, significantly reducing the need for reprinting.

3.2 Clean Appearance

The anti-scratch lamination undergoes a matte finish treatment, thereby reducing the reflection and fingerprints on the product.

This is very helpful in making the cover of the packaging box and the display board look very clean and professional.

And in the videos of the customers opening the boxes, they all looked very beautiful.

4. Common Uses

In fact, for this kind of craftsmanship, it can be seen everywhere around us. For instance, the common restaurant menus

are coated with a anti-scratch lamination, which can significantly protect the products from damage.

For another example, the luxurious packaging gift box maintains the sophistication of the box with a anti-scratch lamination

and is less likely to leave scratches, thereby enhancing the customer's experience.

5. Cost & Sustainability

The material cost of the anti-scratch lamination is 10% to 15% higher than that of ordinary lamination, but its long-term value is obvious.

This is because the return rate of the products produced is lower, so the demand for changing orders will also be less.

And the anti-scratch lamination also facilitates easier recycling.

6. Conclusion

The anti-scratch matte lamination combines beauty and durability, making it increasingly popular among people.

It can ensure that your products are delivered intact to the consumers, guarantee that each design is presented perfectly,

and provide consumers with an excellent visual experience.

Jinayon has a very mature technology for anti-scratch matte lamination, and is capable of producing the desired effect.

FAQ

What is anti-scratch lamination?

A matte, transparent polypropylene film coated with micro-hard particles, heat-laminated and UV-cured onto paper or board to create a highly scratch-resistant surface. .

How does it differ from standard glossy or matte lamination?

It offers superior scratch resistance, lower reflection and fingerprint visibility, and longer shelf life without extra coatings.

What is the cost impact and MOQ for global orders?

Material cost is 10–15 % above regular lamination; MOQ is typically 1,000 sheets or 500 finished boxes.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY