Avancerede muligheder for printbarhed og brandforbedring

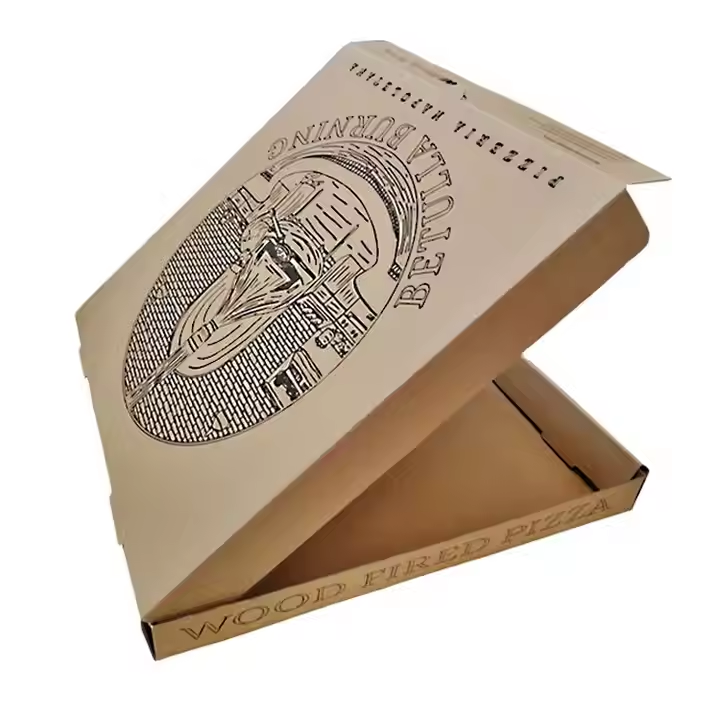

Papiret til emballagekasser har fremragende trykegenskaber, der omdanner almindelig emballage til kraftfulde værktøjer til styrkelse af brandet og giver virksomheder hidtil usete muligheder for at skabe memorerbare kundeoplevelser og øge markedsføringens effektivitet. De overlegne overfladeegenskaber ved papiret til emballagekasser skyldes omhyggeligt kontrollerede produktionsprocesser, der skaber optimal inkbinding og farvegenskaber. Overfladens glathed, opnået gennem præcise kalenderrulleringsmetoder, danner en ideel grund for højopløseligt tryk, der fanger fine detaljer og subtile farveovergange med bemærkelsesværdig klarhed. Denne glatte overflade eliminerer den ru struktur, der kan forårsage utsivning eller ujævn inkdækning, og sikrer, at brandlogos, produktbilleder og markedsføringsmeddelelser fremstår skarpe og professionelle. Papirets kontrollerede porøsitet muliggør optimal inktabsorption og tørring, hvilket forhindrer smudging, samtidig med at den levende farveintensitet bevares gennem hele produktets holdbarhed. Avancerede belægningsformuleringer, specielt udviklet til papir til emballagekasser, forbedrer trykkvaliteten ved at sikre konsekvent inktfasthed og forhindre gennemsynseffekter, der kunne kompromittere udseendet af trykte grafikker på bagsider. Materialets dimensionelle stabilitet forhindrer forvrængning under trykprocesser og sikrer nøjagtig registrering af flere farver og præcis justering af grafiske elementer. Kompatibilitet med forskellige trykmetoder gør papir til emballagekasser alsidigt anvendeligt til forskellige produktionskrav, fra højhastigheds offsettryk til store oplag til digitaltryk til mindre oplag eller variable dataapplikationer. Materialets fremragende inktklæbning forhindrer sprøjtning eller flaking af trykte overflader, selv når emballager udsættes for håndtering, foldning eller miljøpåvirkninger. Farvematchningsnøjagtighed forbedres af papirets neutrale hvide bund, der sikrer konsekvent farvegenskab på tværs af forskellige trykfaciliteter og udstyr. Overfladens ensartethed eliminerer variationer i tryktæthed, der kunne skabe plettet eller strikket udseende, og sikrer professionelle resultater, der afspejler brandets image positivt. Særlige efterbehandlingsmetoder såsom spot-UV-belægning, prægning eller folieprægning kan anvendes på papir til emballagekasser for at skabe premium taktil oplevelser, der differentierer produkter på konkurrencedygtige markeder. Materialets evne til at modtage forskellige inkttyper og belægninger uden delaminering eller overfladedefekter giver designere kreativ frihed til at udvikle innovative emballageløsninger, der fanger forbrugeropmærksomheden og effektivt formidler brandværdier.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY