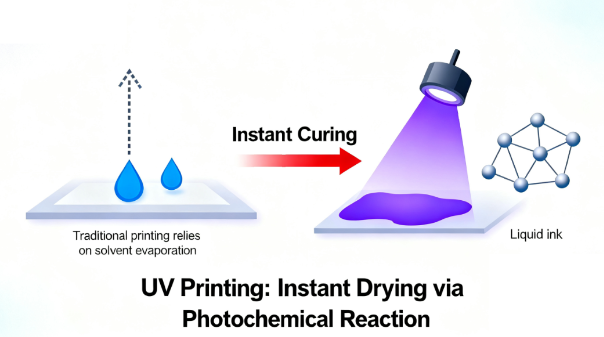

Definition

UV-tryk bruger ultraviolet lys til at omdanne flydende blæk til en fast film, som tørres øjeblikkeligt gennem en fotokemisk reaktion. Denne proces adskiller sig grundlæggende fra traditionelt tryk, der er afhængigt af naturlig fordampning eller tørring med varm luft. I denne artikel undersøger vi den optimale anvendelse af fuldflade UV og spot-UV-tryk i forskellige scenarier.

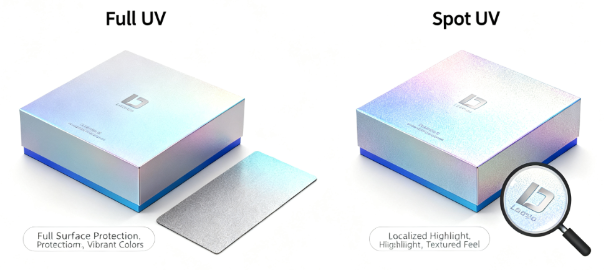

Fuldflade UV og Spot-UV

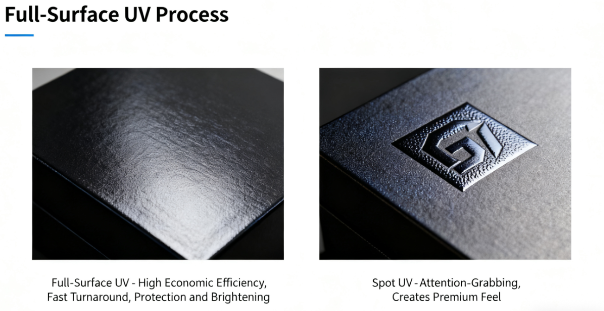

Proces

Fuldflade UV-tryk indebærer påførsel af et ensartet lag af UV-blæk over hele det trykte område. Dette hærdes derefter øjeblikkeligt ved hjælp af UV-lys for at danne en solid beskyttende film. Denne metode kræver ingen justering og er ideel til hurtig produktion.

Spot-UV-tryk kræver en trykplade, hvorigennem UV-blækket overføres til bestemte områder for at sikre præcis justering med designet. Derfor er spot-UV-trykprocessen mere indviklet.

Kost

På grund af forskelle i teknologi varierer omkostningerne. Fuldtrykt UV-belægning kræver ikke brugerdefinerede trykplader, hvilket resulterer i en hurtig produktionsproces og relativt lave omkostninger, hvilket gør den mere økonomisk. Spot-UV-belægning derimod kræver brugerdefinerede trykplader, hvilket fører til højere værktøjsomkostninger og kræver høj præcision og kvalitet. Dette medfører højere tids- og arbejdskraftsomkostninger, hvilket endeligt resulterer i en højere samlet pris.

Virkninger

Fuldtrykt UV-belægning dækker hele overfladen af æsken med en holdbar, gennemsigtig beskyttelsesfilm, primært til vandtæthed og slidstyrke. Forskellige typer lak kan opnå forskellige effekter: blank fuldtrykt UV-belægning skaber en ensartet, spejllignende glans, forbedrer farvemættningen og gør trykte farver mere levende; sløv fuldtrykt UV-belægning reducerer refleksion og forbedrer produktets struktur; og struktureret UV-belægning forbedrer produktets taktilitet.

Spot-UV-beklædning forstærker specifikke områder og bruges ofte i kombination med matt film for at skabe en slående effekt. Spot-UV-beklædning kan også skabe en reliefagtig, struktureret effekt, som heltrykt UV-beklædning ikke kan opnå.

Andre

Set fra et holdbart synspunkt: Fuldoverdekkende UV-beskyttelse giver fremragende beskyttelse ved at dække hele produktets overflade og tilbyder dermed overlegen ridsefasthed. Spot-UV-beskyttelse beskytter derimod kun det påførte område, hvorved resten af produktet er udsat og ikke får tilstrækkelig beskyttelse.

Opsummering

UV-tryk bruges bredt i emballageindustrien på grund af dets fordele. De to primære overfladebehandlingsmetoder – fuldoverflade UV og spot-UV – imødekommer effektivt de fleste behov. Fuldovertrekning med UV er omkostningseffektiv og hurtigere at producere, og giver beskyttelse samt oplysende effekter; spot-UV tiltrækker effektivt kundernes opmærksomhed og skaber et premium-indtryk af produktet. Derfor kan forbrugerne vælge forskellige processer ud fra deres behov for at opnå den bedst mulige produkts virkning.

Jinayon er udstyret med avanceret UV-trykudstyr, som kan opfylde alle dine krav.

Ofte stillede spørgsmål

Hvad er UV-tryk, og hvordan fungerer det?

UV-tryk er en avanceret teknik, der bruger ultraviolet lys til øjeblikkeligt at hærde specielle blæk. I modsætning til traditionelt tryk, der er afhængigt af langsom lufttørring, udløser UV-lys en fotokemisk reaktion, der straks omdanner flydende blæk til en solid, holdbar film ved kontakt.

Hvad er forskellen mellem fuldoverflade UV og spot-UV-beklædning?

Fuld UV-belægning dækker hele overfladen med et ensartet beskyttende lag, hvilket giver komplet beskyttelse mod ridser samt enten en blank eller sløret finish. Spot-UV påfører belægning kun på specifikke designelementer og skaber hævede strukturer og markant visuel kontrast i forhold til ubelagte områder.

Hvilken UV-metode er mest omkostningseffektiv til emballage?

Fuld UV-belægning er generelt mere økonomisk, da den ikke kræver brugerdefinerede plader og muliggør hurtigere produktion.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY