Kustannustehokkaat toiminnot ja liiketoimintatehokkuus

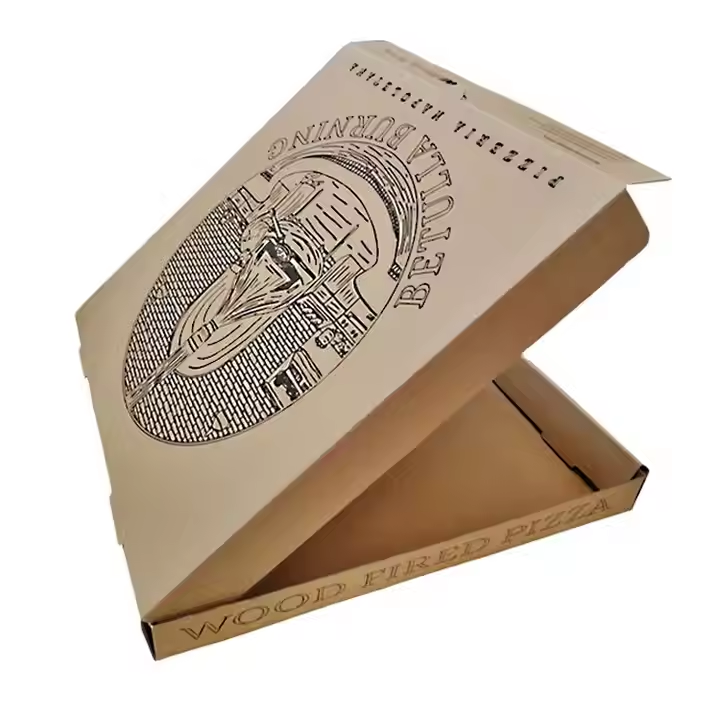

Ruokapakkaukseen tarkoitettu paperilaatikko muuttaa ruokahuollon toimintoja erinomaisen kustannustehokkuuden ja toiminnallisen tehokkuuden parannusten kautta, jotka vaikuttavat suoraan ravintoloiden, catering-yhtiöiden ja ruokakuljetuspalvelujen voitontasoon. Ruokapakkaukseen tarkoitetun paperilaatikon alustavat investointikustannukset pysyvät kilpailukykyisinä vaihtoehtoisten pakkausratkaisujen kanssa samalla tarjoten parempaa pitkän aikavälin arvoa pienentämällä varastointitarpeita, yksinkertaistamalla varastonhallintaa ja poistamalla uudelleenkäytettäviin säiliöihin liittyvät pesu- ja desinfiointikustannukset. Paperipakkauksen kevyt rakenne tuo merkittäviä säästöjä kuljetuskustannuksissa, sillä kuljetuskustannukset laskevat suhteellisesti paketin painon vähentyessä, mikä mahdollistaa yrityksille toimitusreittien optimoinnin ja polttoaineen kulutuksen vähentämisen jakelun verkoissa. Varastointitehokkuus maksimoi arvokasta ravintolatilaa, koska ruokapakkaukseen tarkoitetut paperilaatikot pinotaan tiiviisti litteissä muodoissa ja vaativat huomattavasti vähemmän varastointitilaa verrattuna kömpelöihin muovivaihtoehtoihin, jotka vievät kalliina käyvää keittiö- ja varastotilaa. Työvoimakustannusten aleneminen johtuu yksinkertaisemmista pakausharjoituksista, sillä paperilaatikon kokoaminen ei vaadi erityiskoulutusta tai monimutkaisia kokoonpanoprosesseja, jolloin henkilökunta voi keskittyä keskeisiin ruoanlaitto- ja asiakaspalvelutehtäviin. Ruokapakkaukseen tarkoitetun paperilaatikon pesu- ja desinfiointivaatimusten poistaminen poistaa jatkuvat toiminnalliset kustannukset, mukaan lukien veden, pesuaineiden, energian ja työvoimakustannukset, jotka liittyvät uudelleenkäytettävien säiliöiden puhdistamiseen, tarjoten välittömiä ja jatkuvia säästöjä. Varastonhallinta helpottuu paperipakkauksen ansiosta, koska yhtenäiset mitat ja standardoidut määritelmät yksinkertaistavat tilausprosesseja ja vähentävät useiden eri säiliötyyppien ylläpidon monimutkaisuutta eri ruokalistan tuotteille. Paperipakkauksen kestävyysominaisuudet minimoivat korvauskustannukset vahingoista tai kulumisesta, koska nämä säiliöt säilyttävät rakenteellisen eheytensä normaalien käyttöjaksojen ajan ilman, että niitä tarvitsee korvata usein. Asiakastyytyväisyys paranee suoraan liittyen lisääntyneeseen tulokkuuteen, sillä paperipakkauksen ammattimainen ulkonäkö ja toiminnallisuus parantavat brändin imagoa ja kannustavat toistuvasti palautumaan asiakkaita. Sääntelyvaatimusten noudattamiseen liittyvät kustannukset laskevat paperipakkauksen myötä, koska nämä säiliöt täyttävät vakiintuneet turvallisuusstandardit ilman, että niiden käyttö edellyttää lisäsertifikaatteja tai erikoiskäsittelymenettelyjä, jotka lisäävät toiminnallista monimutkaisuutta ja niihin liittyviä kustannuksia.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY