Laatikon sisävuorauksen merkitys

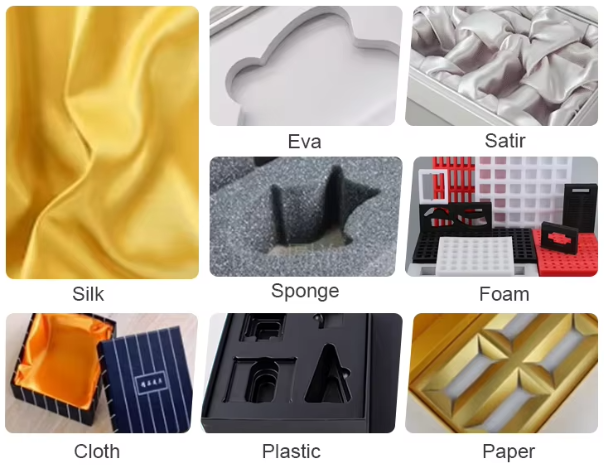

Pakkausta suunniteltaessa sisäisen välimateriaalin valinta on ratkaisevan tärkeää, jotta tuote säilyy ehjänä pudotustesteissä ja esitetään asiakkaille mahdollisimman houkuttelevassa muodossa. Ihanteellinen materiaali riippuu tuotteen erityisvaatimuksista samalla kun otetaan huomioon kustannukset, kestävyys ja brändiin sopiva esteettisyys. Yleisiä vaihtoehtoja ovat EVA-väliosa, Pearly-vaahto (EPE), paperiväliosa ja tiheä karvaton vaahtomuovi. Jokaisella materiaalilla on omat etunsa vaimennusominaisuuksissa, painossa, visuaalisessa ilmeessä ja ympäristövaikutuksissa. Näin ollen "paras" vaihtoehto vaihtelee tilanteen mukaan. Tämä opas tarjoaa analyysin tuotteen teknisten tietojen perusteella ja korostaa vahvuuksia, heikkouksia ja käyttökohteita, jotta voit valita sopivimman materiaalin ja vähentää turhia kokeilukustannuksia.

EVA-vaahdotus

Määritelmä

EVA on tyyppi termoplastista polymeeriä, nimittäin etyleeni-vinyyliasetaatti-kopolymeriä. Sillä on tiivis rakenne, se on joustava ja sillä on erinomainen kimmoisuus. Pinta on siloinen ja hieno. EVA-vaa'an tiheys vaihtelee yleensä 30–80 kg/m³ välillä. Sitä voidaan säätää tarkasti vaa'ottavan aineen määrällä ja prosessiparametreilla, jotta voidaan täyttää erilaiset kovuus- ja kimmoisuusvaatimukset.

Edut ja haitat

Edut

EVA-materiaalilla on korkea joustavuus ja kulumisvastus. Lisäksi forvy-kartongi paino on huomattavasti kevyempi, mikä voi merkittävästi vähentää logistiikkakustannuksia. Lisäksi sen tiheä sisäinen rakenne ei ime vettä ja sillä on erinomainen kosteudenkestävyys. Lisäksi se on erittäin kimmoinen ja voi jakaa ulkoiset iskut voimalla, saavuttaen puskurivaikutuksen. EVA-levyn tiheys vaihtelee yleensä 30–80 kg/m³ välillä. Näin ollen EVA-vaadilla voidaan tehokkaasti estää tärinä ja pudotukset sekä selviytyä paremmin kovasta kuljetuksesta. Samalla sillä on korkea esteettinen arvo ja se voi tehokkaasti parantaa brändin arvostusta.

Epäkohdat

Raaka-aineiden korkean hinnan vuoksi pienet erät voivat aiheuttaa budjetin nousua. Yleensä se on kustannustehokasta vain, kun määrä on vähintään 1 000 kappaletta. Toiseksi EVA:n kimmoisuus on rajallinen. Jos sitä puristetaan usein ja pitkään, siinä voi tapahtua pysyvää muodonmuutosta, eikä sitä suositella tilanteisiin, joissa tarvitaan jatkuvaa puristusta. Lisäksi EVA-materiaali saattaa muuttua tahmeaksi ja romahtaa pitkäaikaisessa korkean lämmön vaikutuksessa, mikä tekee siitä sopimattoman korkeissa lämpötiloissa.

Käyttöskenaarioiden suositus

EVA-materiaalin etujen vuoksi sitä käytetään laajasti erilaisten tuotteiden pakkauksissa: Korkealaatuisissa kosmetiikkatuotteissa EVA luo tehokkaasti juhlatunnelman avattaessa laatikkoa, ja se tukee hyvin kosmetiikkatuotteita. Räätälöityjen värien yhdistäminen pehmeään takkiin antaa kuluttajalle mahdollisuuden kokea viimeistelty ylellinen tuntuma. Viini- ja lahjatuotteiden aloilla EVA:n muovattavuutta ja iskunkestävyyttä hyödynnetään suojaamaan viinipullot tai lahjat kuljetuksen aikana vahingoittumiselta. Samalla eri osastojen avulla voidaan saavuttaa monenlaisia tuoteyhdistelmiä, jotka täyttävät erilaisten lahjaruutujen monipuoliset tarpeet. Ylellisten korujen teollisuudessa EVA:ta ja takkia käytetään yleisesti yhdessä, jolloin sormukset ja korut hohtavat valossa eivätkä heilahtele. Digitaalialalla se voi tarkasti sopua digitaalisten tuotteiden ääriviivoihin, ja eri kerrosten avulla voidaan luoda erillisiä tiloja sijoittaa yhteensopivat tuotteet. Eri aloilla EVA-villityksen ulkonäkö, toimivuus ja brändin ylellisyys voivat tuoda lisäarvoa tuotteisiin.

Helminen vaahto

Määritelmä

Helminen vaahto (EPE) on fysikaalisella vaahtoamisella valmistettu korkeamolekyylinen vaahtomateriaali, joka on tehty alhaisesta tiheydestä olevasta polyeteenistä (LDPE). Sen rakenteessa on lukemattomia itsenäisiä ja tasaisia kuplia. Ulkonäön vuoksi, joka muistuttaa helmiä, sitä kutsutaan nimellä "helminen vaahto".

Edut ja haitat

Edut

Helmisen vaahton materiaali on kevyt ja kimmoisa, ja sillä on myös erinomainen iskunkestävyys, äänieristys- ja kosteudenestop ominaisuudet. Se kestää hyvin kemiallista korroosiota, on ympäristöystävällinen ja kierrätettävä. Lisäksi helminen vaahto on helppo leikata ja käsitellä. Sen hinta on lisäksi merkittävästi alhaisempi kuin EVA-muovin, mikä tekee siitä kustannustehokkaamman vaihtoehdon suurissa tilauksissa.

Epäkohdat

Helmen vaahtoa käytetään yleisesti pakkaussuojaukseen tuotteiden suojaamiseksi kuljetuksen aikana. Helmen vaahton heikko rakenne ei kuitenkaan täytä brändien tekstiivaa koskevia vaatimuksia verrattuna EVA:han. Lisäksi helmen vaahon pinta on pehmeä, jolloin siihen jää helposti kynsisuuria, se repeää helposti ja palautuskyky on heikko. Lisäksi helmen vaahto on palavaa materiaalia, jolloin sen käytössä tulee ottaa paloturvallisuustoimenpiteitä.

Käyttöskenaarioiden suositus

Pearllivilla on materiaali, jota käytetään laajasti pakkausteollisuudessa sen edullisen hinnan, kevyen painon ja erinomaisen iskunvaimennuksen vuoksi. Se on vähitellen saanut käyttäjien hyväksynnän ja suosiota. Esimerkiksi verkkokaupassa saadessamme tuotteita, niiden ympärille on usein tiukasti kiedottu pearllivillaa, jotta ne eivät vaurioidu. Lisäksi ristiriippuvuustuotteiden käsittelyssä suurin osa asiakkaista suosii pearllivillaa pakkauksien sisävuorauksena, koska se estää tuotteiden vaurioitumista pitkien matkojen aikana ja vähentää kustannuksia tehokkaasti. Joululahjojen tapauksessa pearllivilla voi kustannusten säästämiseksi ja tuotteiden suojaamiseksi hyödyntää omia etujaan. Sen leikattavuuden ja runsaan värivalikoiman ansiosta sitä käytetään usein koristeellisiin muotoihin, kuten pienten joulilumihiutaleiden muotoiluun, luomaan juhla tunnelmaa. Näin ollen pearllivilla on monien etujensa vuoksi yhä suositumpi ja tarjoaa turvallisuuden tunnetta erilaisiin pakkauslaatuihin.

Korkean tiheyden vaahtomuovi

Määritelmä

Korkeatiheyksinen vaahto on valmistettu polyuretaanivaahtomateriaalista. Korkeatiheyksisen vaahton kovuutta voidaan säätää muuttamalla vaahtoamiskaavaa.

Edut ja haitat

Edut

Korkeatiheyksisellä vaahtolla on erinomaiset tukiominaisuudet, jotka voivat tehokkaasti suojella tuotetta. Se on erittäin kimmoisa, palautuu nopeasti puristuksen jälkeen, ei ole altis romahtamiselle eikä repeä helposti. Korkeatiheyksisen vaahton rakenne on hienojakoisa, ja pakkausteollisuudessa sen hinta on alhaisempi kuin EVA-muovilla mutta korkeampi kuin perunavilla. Pienille esineille se voi riittävästi täyttää tuotteen suojaamisvaatimukset. Lisäksi sillä on vahva muovautuvuus, mikä tekee siitä sopivan tuotteiden kiinnittämiseen epäsäännöllisiin muotoihin ja se sopii hyvin tuotteen kaarevuuslinjoihin.

Epäkohdat

Kantavuus on rajallinen ja heikompi kuin timanttivillalla ja EVA:lla. Lisäksi sen käsittelyvaatimukset ovat melko korkeat. Jos tuotannon edellyttämät näytteet on valmistettava ensin, muottien kustannukset ovat erittäin korkeat. Sen lisäksi sen lämmön hajaantuminen ja hengittävyys ovat huonoja.

Käyttöskenaarioiden suositus

Tiheän muovivillan vahvan muovattavuuden vuoksi sitä käytetään laajasti eri tilanteissa: esimerkiksi autoteollisuudessa sitä voidaan käyttää auto-osien pakkaamiseen, se sopii täydellisesti osien kaareviin pintoihin ja tarjoaa suojauksen; lemmikkieläinteollisuudessa Tiheää muovivillaa voidaan leikata eri muodoissa, kuten kissan kynsien ja lelujen, kuluttajakokemuksen parantamiseksi; lahjaruutateollisuudessa sitä käytetään myös monien kaarevien tuotteiden pakkaamiseen, pitäen ne tarkasti paikallaan ja varmistamalla niiden vakautta... Siksi Tiheä muovivilla on kuin kaiken kattava "meri", joka täysin sopii tuotteisiin ja parantaa avauskokemusta.

Paperi erottaa

Määritelmä

Paper insert -rakennetta käytetään yleensä tuotteiden kiinnittämiseen, tukemiseen, erottamiseen tai kohottamiseen pakkauksissa. Se valmistetaan tavallisesti 300–400 g/m² paineista valkoista korttipaperia, kraft-paperia tai pahvia, joita käsitellään esimerkiksi leikkaamalla, taittamalla ja taivutuksella.

Edut ja haitat

Edut

Paper insert on kustannustehokkain ja ympäristöystävällisin vaihtoehto laatikoiden sisustusmateriaaleihin. Sitä voidaan käyttää täysivärilatauksessa, UV-tulostuksessa ja foliopainatuksessa, mikä parantaa sen visuaalista houkuttelevuutta. Lisäksi se on kevyempi kuin EVA, mikä vähentää tehokkaasti toimituskustannuksia. Valitsemalla eri tyyppisiä pahveja tai paperikartonneja voidaan täyttää erilaiset kantavuusvaatimukset.

Epäkohdat

Paperiinsertti on huonosti vesitiivis, repeää helposti ja sen uudelleenkäyttöaste on alhainen. Sen vaimennusteho on heikompi verrattuna muihin sisäkalusteisiin. Lisäksi, jos paperiinsertin valmistusprosessi on monimutkainen, työkustannukset voivat kasvaa ja ylittää jopa EVA:n kustannukset. Lisäksi paperiinsertin paksuus on rajoitettu; yli 8 mm:n paksuisena sitä on vaikea taivuttaa.

Käyttöskenaarioiden suositus

Paper insert:tä käytetään laajasti ja sitä tunnetaan yleisesti: Esimerkiksi kauneusteollisuudessa sitä käytetään irrotettavien kalenterojen vuorauksena brändeille, mikä luo suuren juhlatunnelman kuluttajille ja parantaa uudelleenostotodennäköisyyttä, aivan kuin avattaisi lahjalaukku. Kahvamerkeissä tuotteet kiinnitetään paperivillauksella ja yhdistämällä erilaisia painatuksia ja muita prosesseja luodaan kahvilan ilmaston mukainen esitystila, mikä parantaa merkittävästi laatikon avaamisen kokemusta. Yksi valokuva voi helposti muuttua maksuttomaksi mainosjulisteeksi. Kyseessä ovat monimutkaisemmat skenaariot, mutta paper insert:tä käytetään yleensä pienten erien tilauksiin ja kevyiden tuotteiden paketteihin kustannusten säästämiseksi. Kartongin monikäyttöisyys mahdollistaa sen merkityksen useilla eri tahoilla.

Yhteenveto

Siksi laatikossa käytettävän sisävuorauksen valinta tulisi perustua useiden tekijöiden yhdistelmään. Tässä pieni riimikelpoinen ohje: Kun valitset sisävuorauksen, ota huomioon tuote – EVAn käytä luksustuotteisiin; taloudellisuus vaatii perlitevaa; kaareviin pintoihin soveltuu tiheä kynsisieni; kevyt ja ympäristöystävällinen vaihtoehto on paperi erikoisvuoraus. Oikean materiaalin valinta maksimoi hyödyn!

Edellä mainitut vuoraukset, Jinayon voimme suositella sinulle parhaan mahdollisen vuorauksen.

UKK

Kuinka valitsen parhaan sisävuorausmateriaalin tuotteiden pakkausta varten?

Paras valinta riippuu useiden tuotteelle ominaisten tekijöiden yhdistelmästä. Sinun tulisi ottaa huomioon sen herkkyys, paino ja muoto, budjetti, kestävyystavoitteet ja haluttu brändin estetiikka.

Mikä ovat EVAn pääasialliset edut ja mille tuotteille se soveltuu parhaiten?

EVA-vaa'an tarjoaa suuren joustavuuden, erinomaisen isonvaimennuksen, kosteudenkestävyyden sekä premium- ja sileän tekstuurin, joka korostaa brändin arvostusta. Sitä voidaan käyttää erityisesti korkealaatuisissa tuotteissa, kuten kosmetiikassa, luksuslahjoissa, koruissa ja elektroniikassa.

Tuotteelleni on ominaista ainutlaatuinen, epäsäännöllinen muoto. Mikä materiaali sopii parhaiten mukautuvan ja tiiviin istuman toteuttamiseen?

Korkean tiheyden kuitu on täysin sopiva tähän tarkoitukseen. Sillä on voimakkain muovautuvuus ja sitä voidaan muokata täydelliseksi tuotteiden kaartuvien ja epäsäännöllisten muotojen tueksi tarjoten erinomainen suojauksen sekä räätälöidyn pakkauksen kokemuksen.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY