Superieure milieuduurzaamheid en integratie van de circulaire economie

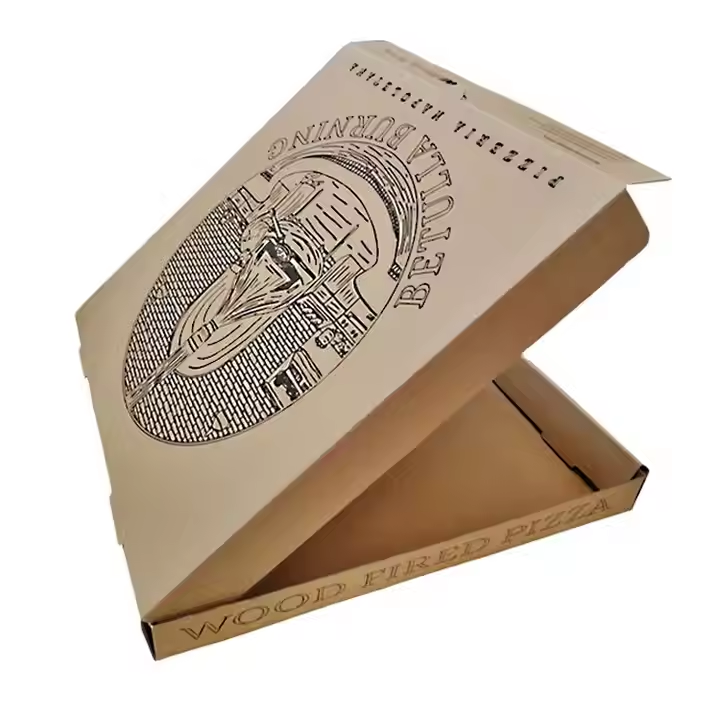

Kwaliteitsvoldoende papieren dozen zijn een voorbeeld van uitstekende milieuduurzaamheid door integratie in de circulaire economie, wat het ecologische effect minimaliseert en tegelijkertijd de efficiëntie van hulpbronnengebruik maximaliseert gedurende de gehele levenscyclus van het product. Deze innovatieve verpakkingsoplossingen gebruiken post-consument recyclingmateriaal waarvan het percentage vaak meer dan 85% bedraagt, waardoor de vraag naar nieuw materiaal direct wordt verlaagd en afvalverwijderingsinitiatieven worden ondersteund die voorkomen dat waardevolle grondstoffen terechtkomen op stortplaatsen. Het productieproces maakt gebruik van hernieuwbare energiebronnen en waterrecyclingsystemen die de koolstofvoetafdruk met tot 60% verminderen in vergelijking met conventionele verpakkingsproductiemethoden. Kwaliteitsvoldoende papieren dozen zijn ontworpen om volledig biologisch afbreekbaar te zijn binnen 90 dagen onder juiste composteeromstandigheden, zodat ze voedingsstoffen teruggeven aan de bodem in plaats van als milieuvervuiler te blijven bestaan. De productiefaciliteiten werken onder strikte milieumanagementsystemen, inclusief ISO 14001-certificering, en passen continue verbetertrajecten toe die de afvalproductie minimaliseren en het hulpbronnengebruik optimaliseren. Certificering door de Forest Stewardship Council (FSC) garandeert dat alle grondstoffen afkomstig zijn uit verantwoord beheerde bossen die biodiversiteit behouden, lokale gemeenschappen ondersteunen en zich op natuurlijke wijze regenereren. De lichtgewicht constructie van kwaliteitsvoldoende papieren dozen vermindert transportemissies doordat er per zending meer producten kunnen worden vervoerd, terwijl de beschermende functie intact blijft. Mogelijkheden voor eindverwerking omvatten standaard ophaalrecyclingprogramma's, industriële composteerinstallaties en gespecialiseerde papierrecyclingstromen die gebruikte dozen omzetten in nieuwe producten binnen gesloten lussen. De eliminatie van niet-recycleerbare onderdelen zoals plastic vensters, metalen hechtingen en chemische lijmverbindingen zorgt voor volledige materiaalherwinning zonder risico op verontreiniging. Kwaliteitsvoldoende papieren dozen ondersteunen de rapportagevereisten voor bedrijfsduurzaamheid door gecertificeerde milieuvorderingen te bieden, zoals vermindering van de koolstofvoetafdruk, cijfers over afvalverwijdering en statistieken over het gebruik van hernieuwbare materialen. De circulaire ontwerpprincipes strekken zich uit tot verpakkingsoptimalisatie, waarmee minder materiaal wordt gebruikt terwijl de structurele prestaties behouden blijven, wat tot 25% materiaalbesparing oplevert dankzij geavanceerde engineeringtechnieken. Consumenteneducatie-initiatieven die bij deze dozen worden geleverd, bevorderen correcte verwijderingspraktijken en benadrukken de milieuvorderingen, waardoor positieve merkassociaties ontstaan en bredere bewustwordingscampagnes over duurzaamheid worden ondersteund.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY