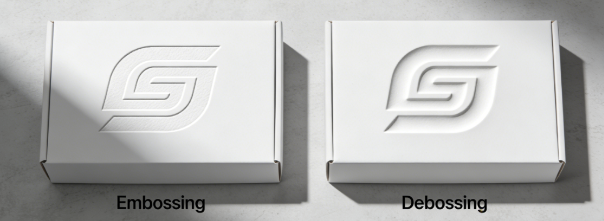

В сфере персонализированной упаковки тактильные ощущения также играют ключевую роль в выделении бренда. Поэтому тиснение и глубокая печать — это два способа поверхностной обработки, придающие тактильные и трёхмерные эффекты. Но в чём между ними разница?

Тиснение создает объемный 3D-эффект на поверхности упаковки. Требуется специальная форма, и давление применяется для поднятия рисунка вверх, создавая тактильную текстуру. Часто используется в сочетании с тиснением фольгой на логотипах, узорах и т.д., чтобы создать роскошный и многослойный эффект.

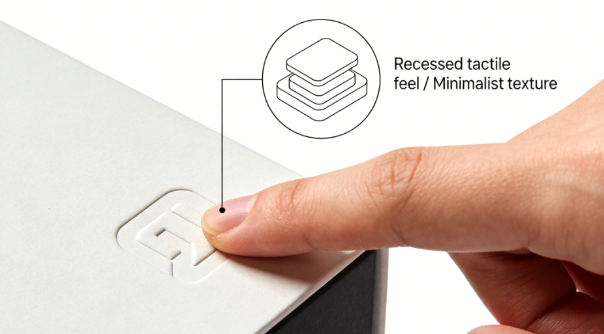

Тиснение вдавливает рисунок вглубь материала, создавая тактильное ощущение углубления. Передает сдержанный, элегантный и минималистичный характер, идеально подходит для минималистичной упаковки или брендов, стремящихся к изысканному и неброскому стилю. Как и тиснение, требует специальной формы и применяет обратное давление.

Оба процесса широко используются в упаковке и обеспечивают потребителям превосходное тактильное восприятие. Их можно комбинировать с тиснением фольгой, сплошным УФ-покрытием и другими процессами, чтобы усилить двойное воздействие визуальных и тактильных ощущений. Их также можно совмещать, чтобы создать многослойный эффект на одной упаковке.

Контакты Джинаон для комплексных решений в области упаковки.

Часто задаваемые вопросы

В чем ключевое различие между тиснением и глубоким тиснением?

Тиснение поднимает рисунок над поверхностью, создавая тактильный трехмерный эффект, в то время как глубокое тиснение вдавливает его внутрь, формируя углубленное изображение.

Можно ли совмещать тиснение или глубокое тиснение с другими техниками отделки?

Да. Оба варианта хорошо сочетаются с фольгированием для дополнительного блеска или со сплошным УФ-покрытием для контраста текстур. Сочетание техник создаёт многоуровневую сенсорную привлекательность, которая повышает качество впечатления от распаковки.

Какие факторы влияют на стоимость тиснения/глубокого тиснения?

Ключевые факторы включают сложность формы, толщину материала, объём производства и использование других видов отделки в сочетании. Тиснение, как правило, требует несколько большей точности и может потребовать более высоких затрат на настройку.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY