Comprehensive Customization and Design Solutions

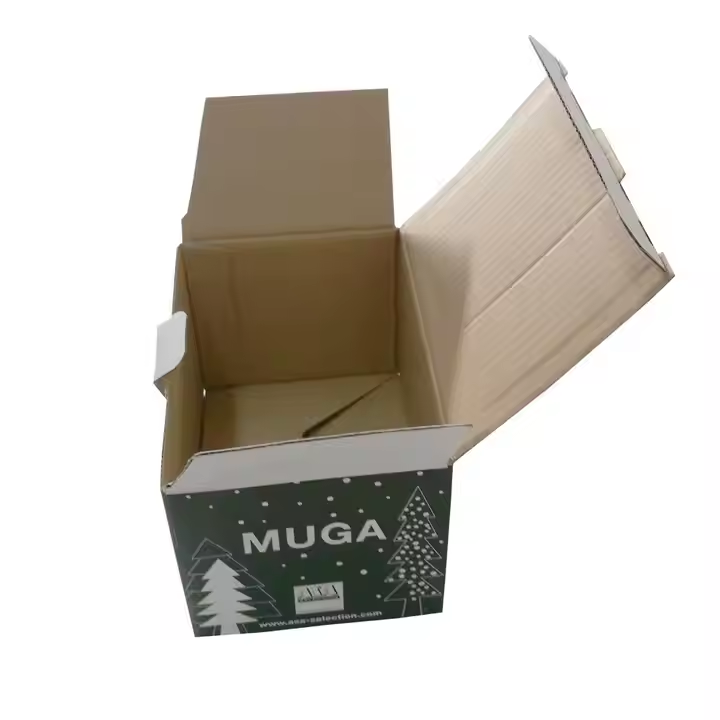

The customization capabilities of a corrugated box company extend far beyond standard shipping containers to encompass sophisticated design solutions that enhance product presentation, protection, and brand recognition. Professional packaging engineers collaborate directly with clients to analyze product specifications, shipping requirements, and marketing objectives, developing tailored solutions that optimize both functionality and visual impact. Computer-aided design software enables rapid prototyping and three-dimensional visualization, allowing customers to evaluate packaging concepts before committing to production tooling. Structural design expertise addresses unique challenges such as fragile item protection, weight distribution, and stacking strength requirements through specialized construction techniques including multi-wall configurations, internal dividers, and shock-absorbing inserts. The corrugated box company maintains extensive libraries of proven designs while continuously developing innovative solutions for emerging market needs. Custom printing services accommodate complex graphics, multiple colors, and special finishes including aqueous coatings, UV treatments, and embossed textures that create premium packaging experiences. Die-cutting capabilities produce intricate shapes, viewing windows, carrying handles, and promotional features that differentiate products in competitive markets. Size optimization services analyze product dimensions and shipping requirements to minimize material usage while maximizing protection, resulting in cost savings and environmental benefits. Specialized applications include food-safe coatings for direct product contact, moisture barriers for climate-sensitive items, and static-dissipative materials for electronic components. The design process incorporates sustainability considerations such as recyclability, material efficiency, and end-of-life disposal options. Rapid sampling services provide physical prototypes for testing and approval, ensuring design accuracy before full production begins. Collaborative design reviews involve cross-functional teams including marketing, logistics, and manufacturing professionals to ensure comprehensive solution development. The corrugated box company's customization expertise transforms standard packaging into strategic business tools that enhance customer satisfaction, reduce logistics costs, and strengthen brand positioning in competitive markets.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY