Exceptional Versatility and Customization Capabilities

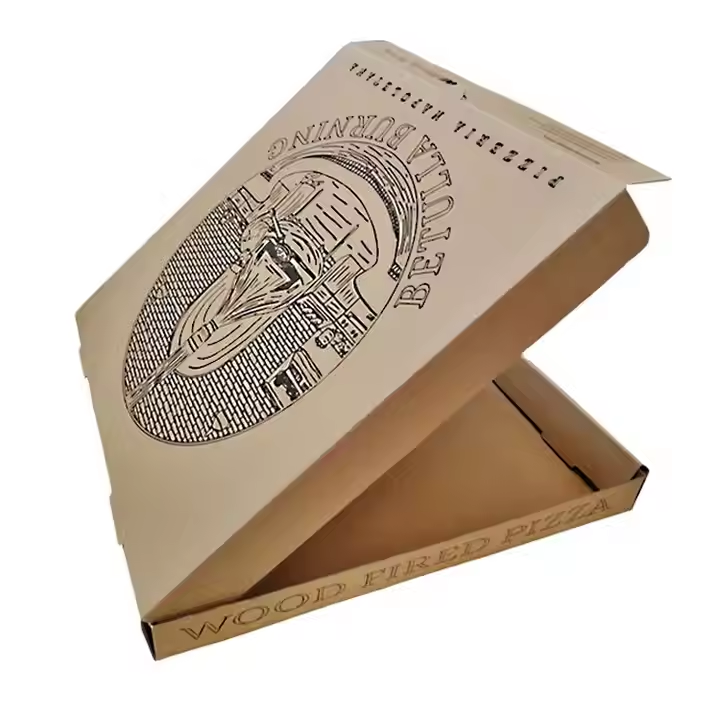

Big corrugated boxes offer unprecedented versatility through extensive customization options that perfectly align with diverse business requirements and specific product protection needs. Custom sizing services enable precise dimensional matching for virtually any product configuration, eliminating wasted space and reducing shipping costs significantly. Die-cutting capabilities produce specialized shapes, windows, handles, and compartment dividers that enhance functionality for unique applications. Printing services transform basic containers into powerful marketing tools through high-resolution graphics, brand messaging, and product identification systems. Multi-color printing options support complex logo reproduction and detailed assembly instructions that improve customer experience. Coating applications provide enhanced moisture resistance, grease barriers, and surface treatments that extend usability in challenging environments. Big corrugated boxes can incorporate tamper-evident features, security perforations, and specialized closure systems that meet stringent regulatory requirements. Food-grade treatments ensure compliance with health department standards for direct food contact applications. Flame-retardant coatings enable safe usage in electronics packaging where fire safety considerations are paramount. The modular design philosophy allows multiple box sizes to nest together efficiently, optimizing storage space utilization and transportation efficiency. Convertible designs enable single containers to serve multiple functions, such as shipping boxes that transform into retail display units. Telescoping constructions accommodate variable product heights while maintaining consistent outer dimensions for standardized handling equipment. Partition systems create organized compartments for multiple items, preventing damage from inter-product contact during shipping. Handle integration facilitates manual handling without requiring additional packaging materials or external hardware. The corrugated substrate accepts various adhesive systems, enabling secure attachment of product documentation, shipping labels, and regulatory compliance markings. Custom perforation patterns create easy-opening features that enhance end-user convenience while maintaining structural integrity during transit. Big corrugated boxes support sustainable packaging initiatives through recycled content options and biodegradable coating alternatives that align with environmental responsibility goals.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY