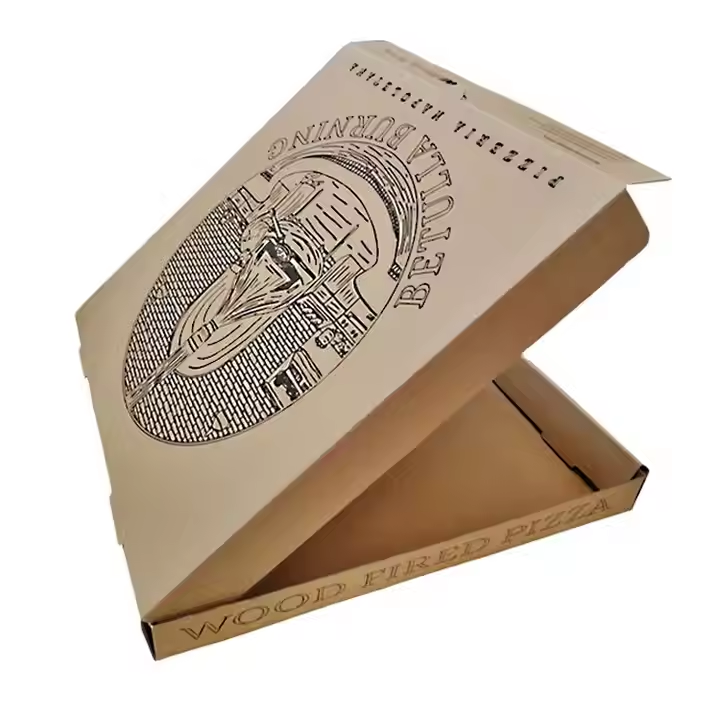

custom packaging box

A custom packaging box represents a tailored solution designed to meet specific branding, protection, and presentation requirements for businesses across various industries. These specialized containers combine functionality with aesthetic appeal, offering companies the opportunity to create memorable unboxing experiences while ensuring product safety during transportation and storage. Custom packaging boxes serve multiple essential functions that extend beyond basic containment. They act as powerful marketing tools, providing extensive surface area for brand messaging, logo placement, and visual storytelling that captures consumer attention at point of sale. The protective function remains paramount, as these boxes shield contents from environmental factors including moisture, temperature fluctuations, physical damage, and contamination during shipping and handling processes. The technological features of modern custom packaging boxes incorporate advanced materials science and engineering principles. Manufacturers utilize corrugated cardboard, kraft paper, rigid chipboard, and eco-friendly alternatives that provide optimal strength-to-weight ratios. Digital printing technology enables high-resolution graphics, vibrant colors, and intricate designs that maintain consistency across production runs. Structural engineering ensures proper dimensional stability, stackability, and compression resistance to withstand supply chain pressures. Smart packaging integration allows incorporation of QR codes, NFC tags, and augmented reality features for enhanced consumer engagement. Applications span numerous sectors including e-commerce, retail, food and beverage, cosmetics, electronics, pharmaceuticals, and luxury goods. E-commerce businesses rely on custom packaging boxes to differentiate their products in crowded marketplaces while ensuring safe delivery to customers. Retail brands utilize these solutions for seasonal promotions, product launches, and limited edition releases. Food companies benefit from specialized barrier coatings and food-grade materials that maintain freshness and comply with safety regulations. The versatility of custom packaging boxes makes them indispensable tools for businesses seeking to enhance their market presence while providing practical protection for their valuable products.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY