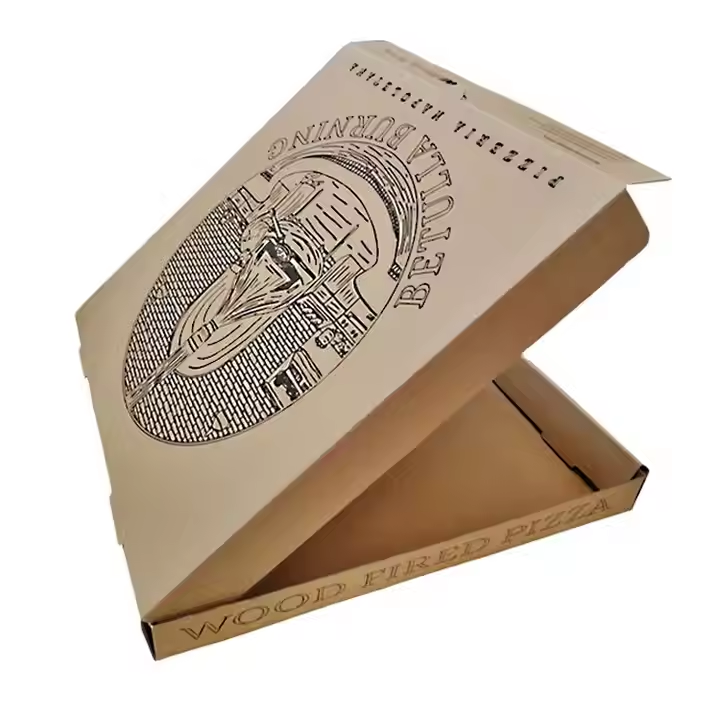

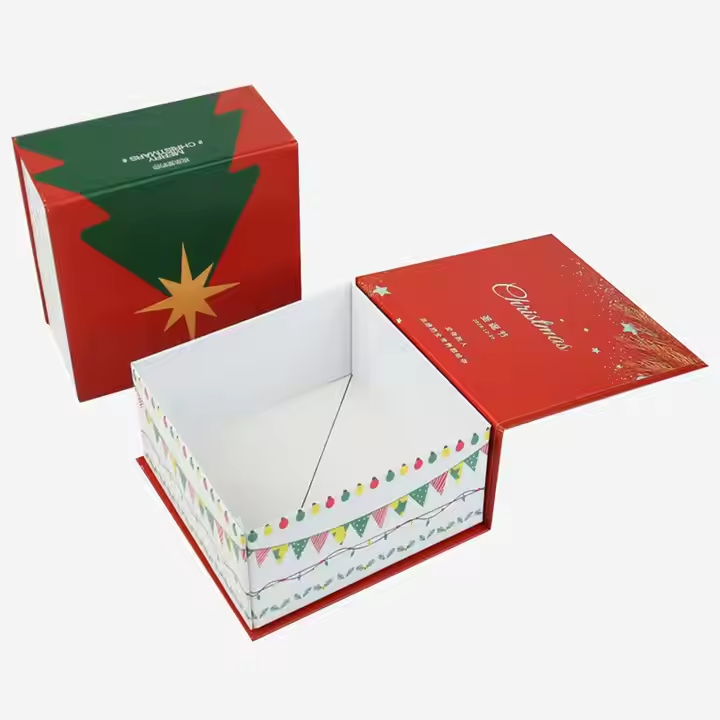

folding box

A folding box represents a revolutionary packaging solution that transforms the traditional approach to storage, shipping, and organization. This innovative container system utilizes advanced engineering principles to create a versatile packaging option that can collapse flat when not in use and expand to full capacity when needed. The folding box combines durability with space-efficiency, making it an essential tool for modern logistics and storage applications. The primary function of a folding box centers on its ability to provide secure containment while maintaining flexibility in storage and transportation. When fully assembled, these containers offer the same protective qualities as traditional rigid boxes, safeguarding contents from external damage, moisture, and contamination. The technological features of folding boxes include precision-engineered fold lines, reinforced corner structures, and interlocking mechanisms that ensure stability during use. Many models incorporate advanced materials such as corrugated cardboard with enhanced strength properties, plastic composites, or even metal alloys depending on the intended application. The design typically features pre-scored fold lines that allow for easy assembly without requiring additional tools or adhesives. Applications for folding boxes span numerous industries and use cases. E-commerce businesses rely heavily on these containers for shipping products to customers, as they can be stored flat in warehouses and assembled on-demand, significantly reducing storage space requirements. Manufacturing companies use folding boxes for component organization and work-in-progress storage. Retail establishments utilize them for seasonal merchandise storage and display purposes. Moving companies and storage facilities appreciate their ability to maximize space efficiency when not in use. The food industry employs specialized folding boxes for packaging and delivery services, while pharmaceutical companies use them for secure transportation of medical supplies and equipment. The versatility of folding box designs allows for customization to meet specific industry requirements, including food-grade materials, tamper-evident features, and specialized closure systems.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY