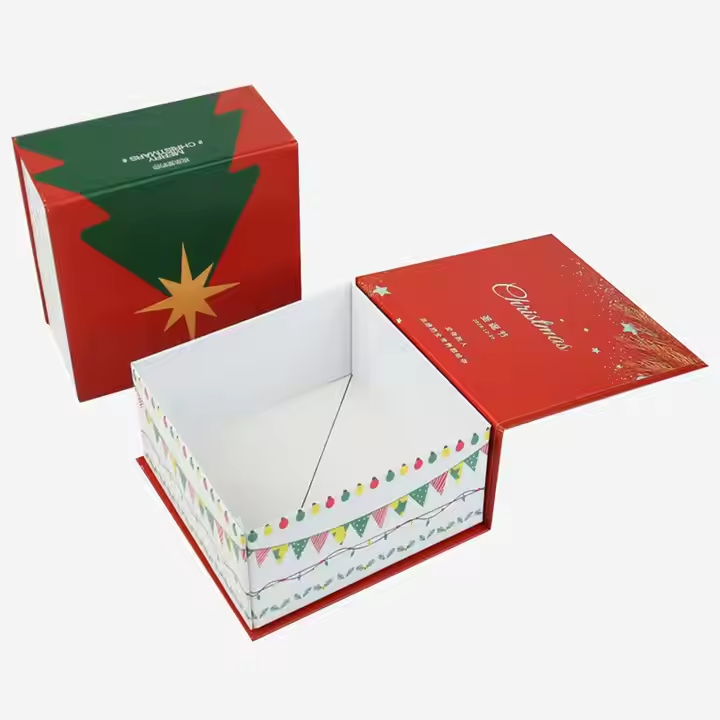

paper boxes for skin care serum

Paper boxes for skin care serum represent an essential packaging solution that combines environmental responsibility with premium product protection. These specialized containers serve as the primary protective barrier for delicate skincare formulations, ensuring product integrity from manufacturing through consumer use. The main functions of paper boxes for skin care serum encompass multiple critical aspects including product safeguarding, brand presentation, and sustainable packaging alternatives. These boxes protect sensitive serum formulations from external factors such as light exposure, temperature fluctuations, and physical damage during transportation and storage. The technological features of modern paper boxes for skin care serum incorporate advanced materials engineering and innovative design methodologies. Manufacturers utilize high-grade cardboard materials treated with specialized coatings that provide moisture resistance while maintaining breathability. The structural design often includes internal cushioning systems, precise fitting mechanisms, and secure closure systems that prevent accidental opening. Advanced printing technologies enable vibrant color reproduction and sophisticated graphics that enhance brand recognition and consumer appeal. Applications of paper boxes for skin care serum extend across various market segments, from luxury skincare brands to emerging organic product lines. These versatile containers accommodate different serum bottle sizes, shapes, and materials, making them suitable for glass vials, plastic dispensers, and dropper bottles. The boxes serve retail environments where visual presentation drives purchasing decisions, e-commerce platforms requiring secure shipping protection, and professional treatment centers maintaining product organization. Contemporary paper boxes for skin care serum also integrate smart packaging technologies, including QR codes for product authentication, augmented reality features for enhanced customer engagement, and tamper-evident seals ensuring product safety. The manufacturing process involves precision cutting, folding techniques, and quality control measures that guarantee consistent dimensions and structural integrity across production batches.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY