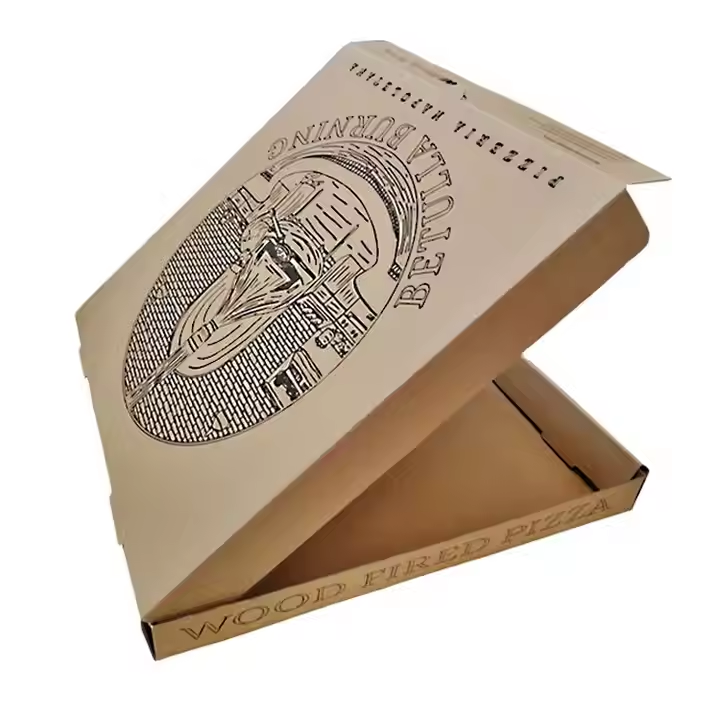

pizza boxes

Pizza boxes represent essential packaging solutions designed specifically for the safe transport and preservation of pizza products. These corrugated cardboard containers serve multiple critical functions in the food service industry, providing structural protection, thermal insulation, and convenient handling capabilities. Modern pizza boxes incorporate advanced materials and engineering principles to maintain food quality during delivery and takeout operations. The primary technological features include specialized corrugated cardboard construction that offers superior strength-to-weight ratios, ensuring boxes remain intact under various transportation conditions. Advanced coating technologies protect against grease penetration while maintaining breathability to prevent moisture buildup that could compromise food texture. Pizza boxes feature strategically designed ventilation systems that balance heat retention with steam release, preventing sogginess while keeping contents warm. Dimensional engineering ensures optimal space utilization while accommodating different pizza sizes ranging from personal portions to large family meals. The folding mechanisms incorporate precision-cut scoring and perforations that enable rapid assembly without compromising structural integrity. Applications span across diverse food service segments including restaurants, delivery services, frozen food manufacturers, and retail establishments. Commercial pizza boxes serve pizzerias, chain restaurants, and independent eateries requiring reliable packaging solutions for customer orders. Food delivery platforms rely extensively on these containers to maintain product quality during transportation. Retail frozen pizza manufacturers utilize specialized pizza boxes for consumer convenience and brand recognition. The versatility extends to catering services, food trucks, and institutional feeding operations. Manufacturing processes employ sustainable materials and eco-friendly production methods, addressing environmental concerns while maintaining performance standards. Quality control systems ensure consistent dimensions, strength characteristics, and food safety compliance across production runs.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY