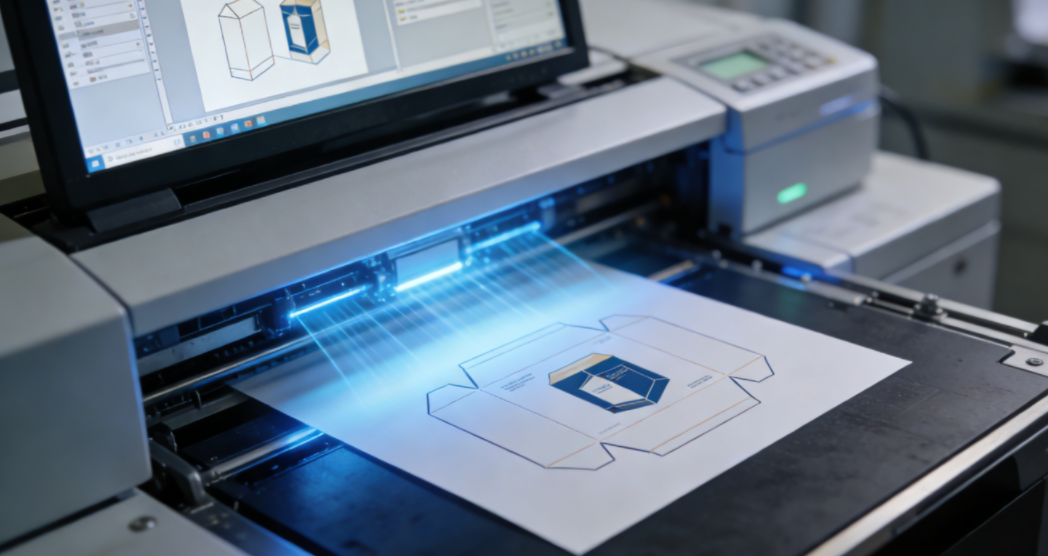

In this fast-paced era of customized packaging, the demand for speed and precision in prototyping is increasing. Therefore, digital prototyping has gradually become a crucial step before production, enabling the rapid production of desired packaging samples. Its efficiency and cost-effectiveness have replaced the time-consuming, labor-intensive, and expensive traditional prototyping methods.

Unlike traditional prototyping, digital prototyping directly uses high-resolution, high-color-rendering printing machines to print materials based on printed files, providing the final product effect while reducing time.

Digital prototyping eliminates the need for physical printing plates and significantly reduces the time required, shortening sample delivery time from weeks to approximately 1-3 days. This speed allows brands to quickly adapt packaging for new product launches, market testing, and keeping up with market trends. Digital prototyping also offers a cost advantage, saving on printing plate expenses and reducing material waste, allowing brands to test multiple design options in the early stages without incurring excessive costs. Furthermore, despite its low cost and speed, digital prototyping does not compromise sample quality. It accurately matches colors and clearly presents details, helping brands verify sample details before mass production and avoiding high error costs.

Therefore, it is recommended to use digital prototyping for initial confirmation, and only supplement with physical proofs for projects with extremely high color requirements.

Contact Jinayon to obtain digital samples of your packaging.

FAQ

How much faster is digital proofing compared to traditional methods?

Digital proofing reduces sample lead time from weeks to just 1–3 days, as it eliminates the need for physical printing plates and streamlines the approval process.

What cost savings can I expect with digital proofing?

Digital proofing saves on plate costs, material waste, and labor. It allows affordable testing of multiple design versions before committing to mass production tooling.

When should I choose digital proofing over a physical press proof?

Use digital proofing for initial design validation, structural checks, and speed-critical projects. For color-sensitive brand elements (e.g., logos), follow up with a physical proof before mass production.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY