When customizing foldable cardboard boxes, a detail often overlooked is the paper's grain direction. Many may think it's unimportant, but this small detail significantly impacts the final product.

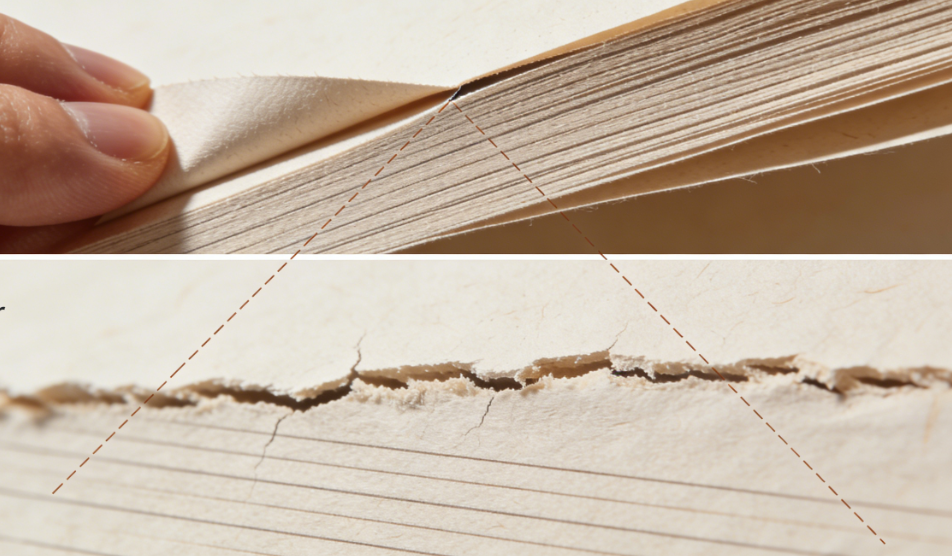

Paper grain refers to the arrangement of the wood fibers within the paper. This is naturally formed during the papermaking process, where the fibers are neatly arranged in one direction, creating the grain. The grain directly affects the paper's bending and folding properties, as well as its shaping. Folding with the grain results in smooth creases, maintaining the packaging's integrity; folding against the grain leads to paper cracking and uneven folds.

In custom packaging, the grain direction also affects printing and material usage. Aligning the folding direction with the grain ensures even ink absorption, preventing color deviations; it also optimizes material cutting, reducing waste. This small detail can have a significant impact on the final packaging quality, brand image, and cost-effectiveness.

Contact Jinayon for a one-stop foldable gift box packaging solution.

FAQ

Why is paper grain direction important for folding boxes?

Folding along the grain direction follows the natural alignment of paper fibers, resulting in clean, smooth creases. Folding against the grain can cause cracking, uneven edges, and compromised structural integrity.

How can I identify the grain direction of paper or cardboard?

Gently bend the sheet—it will curve more easily along the grain direction. You can also observe fiber patterns or consult your paper supplier’s specifications for grain indication.

Does grain direction affect printing quality on packaging?

Yes. Paper absorbs ink differently along versus across the grain. Aligning printing with the grain helps prevent color shifts, blotching, or registration issues, ensuring consistent graphic quality.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY