Edistynyt monitasoinen tulostusteknologia

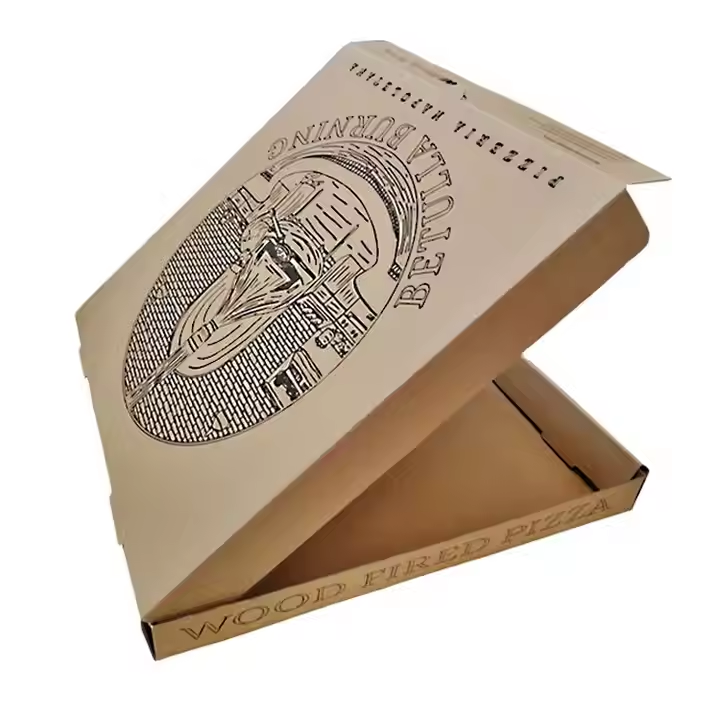

Tulostussuunnittelun painopaperilaatikko sisältää uusimman tason monikerroksisen painoteknologian, joka mullistaa tavalla, jolla brändit esittelevät tuotteitaan kuluttajille. Tämä kehittynyt järjestelmä mahdollistaa useiden mustekerrosten, erikoispäällysteiden ja viimeistelytekniikoiden käytön, mikä luo silmiinpistäviä visuaalisia vaikutelmia, joita ei voida saavuttaa perinteisillä pakkausmenetelmillä. Perustana on tarkka värinsovitus, jossa käytetään edistyneitä spektrofotometrejä, jotta jokainen tulostussuunnittelun painopaperilaatikko säilyttää yhtenäiset brändivärit eri tuotantoserioissa. Korkearesoluutioinen digitaalipainotus mahdollistaa valokuvanlaatuisten kuvien, monimutkaisten logojen ja hienojakoisten graafisten elementtien uudelleentuottamisen erinomaisella selkeydellä ja yksityiskohtaisuudella. Monikerroksinen menetelmä sisältää perusvärit, korostusvalot, metallihopeat ja suojapäällysteet, jotka yhdessä luovat syvyyttä ja visuaalista kiinnostavuutta. Erikoismusteita, kuten lämpösävyjä, valosävyjä tai raapi-ja-haise -muotoelmia, voidaan yhdistää tulostussuunnittelun painopaperilaatikkoon luodakseen vuorovaikutteisia kuluttajakokemuksia, jotka parantavat brändisidettä. Painoprosessi hyödyntää huippuluokan laitteistoa, joka pystyy rekisteröimään useita värejä mikroskooppisen tarkasti, varmistaen, että monimutkaiset suunnittelut kohdistuvat täydellisesti ja säilyttävät ammattimaisen ulkonäön. Edistyneet UV-kuivatusjärjestelmät tarjoavat välittömän kuivumisen ja parannetun kestävyyden, jolloin tulostussuunnittelun painopaperilaatikko kestää hämärtyvyyttä, naarmuja ja kosteusvaurioita koko elinkaarensa ajan. Laadunvalvontajärjestelmät seuraavat värikyvyyttä, rekisteröintitarkkuutta ja viimeistelyn yhtenäisyyttä reaaliajassa, taaten, että jokainen tulostussuunnittelun painopaperilaatikko täyttää tiukat standardit. Teknologia tukee myös muuttuvan datan painamista, mahdollistaen personalisoidut pakkausratkaisut, jotka voivat sisältää yksittäisiä asiakasnimiä, peräkkäisiä numeroita tai aluekohtaisia tietoja tuotantotehokkuutta häiritsemättä. Tämä teknologinen kehittyneisyys muuttaa yksinkertaisen tulostussuunnittelun painopaperilaatikon voimakkaaksi markkinointivälineeksi, joka herättää huomiota, välittää arvoa ja luo muistettavia brändikokemuksia, jotka lisäävät asiakassitoutumista ja toistettuja ostoja.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY