Customization Capabilities and Brand Enhancement Opportunities

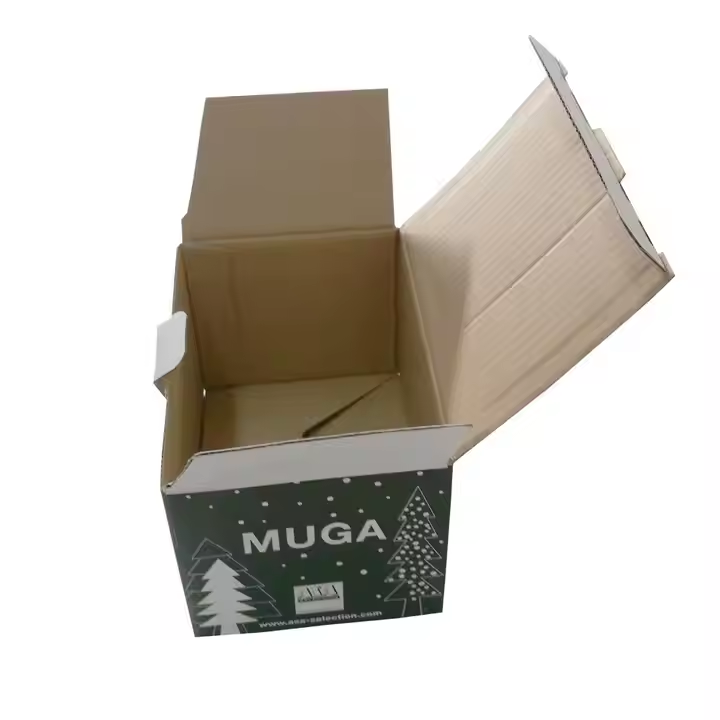

The corrugated box offers unprecedented customization possibilities that enable businesses to create distinctive packaging solutions tailored to specific product requirements and brand positioning strategies. Advanced printing technologies allow for full-color graphics, photographic images, and complex designs to be applied directly to corrugated box surfaces during the manufacturing process. Digital printing capabilities provide cost-effective short-run customization options, enabling businesses to create seasonal packaging, limited edition designs, or personalized corrugated box solutions without minimum order constraints. The corrugated box surface readily accepts various finishing techniques, including spot UV coating, embossing, debossing, and foil stamping, creating premium presentation effects that enhance perceived product value. Structural modifications to corrugated boxes include custom die-cutting options that create unique opening mechanisms, display features, or integrated handles that improve user experience and functionality. The corrugated box design process accommodates specific dimensional requirements, ensuring optimal product fit while minimizing material waste and shipping costs. Window cutouts with clear film inserts allow product visibility while maintaining the protective benefits of corrugated box packaging, ideal for retail applications requiring consumer preview capabilities. Multi-color printing processes enable corrugated boxes to display complex brand graphics, detailed product information, and marketing messages that communicate value propositions effectively to target audiences. The corrugated box surface treatment options include aqueous coatings, varnishes, and laminations that provide enhanced durability, moisture resistance, and visual appeal for premium product applications. Custom scoring and perforation patterns allow corrugated boxes to transform into display stands, shipping containers, or point-of-sale materials, maximizing packaging utility and reducing inventory requirements. The corrugated box manufacturing process supports variable data printing, enabling unique codes, addresses, or personalized messages on individual units for direct marketing campaigns or traceability requirements. Specialty adhesives and closure systems can be integrated into corrugated box designs, providing tamper-evident features, resealable options, or security enhancements that protect high-value products during distribution and storage.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY