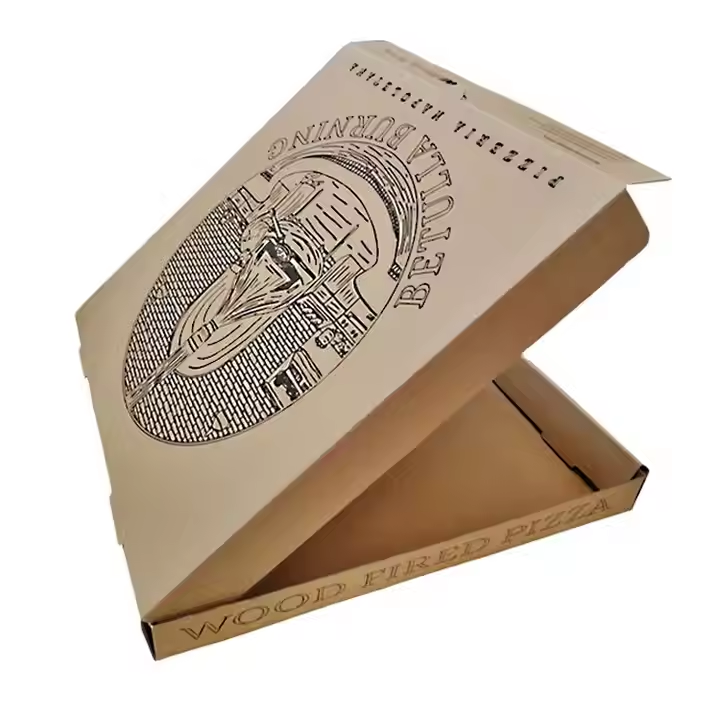

corrugated small box

The corrugated small box represents a fundamental packaging solution that combines durability, versatility, and cost-effectiveness in a compact format. These specialized containers are engineered using corrugated cardboard material, featuring a distinctive fluted layer sandwiched between two flat linerboards, creating an exceptionally strong yet lightweight structure. The corrugated small box serves multiple functions across various industries, primarily designed for shipping, storage, and product protection during transportation. Its technological construction involves precision manufacturing processes that ensure consistent quality and structural integrity. The fluted corrugated design provides superior cushioning properties, effectively absorbing impacts and vibrations that could damage contents during handling and transit. Modern corrugated small box production utilizes advanced adhesive systems and precise cutting techniques to create seamless joints and accurate dimensions. These boxes are manufactured in numerous standardized sizes to accommodate diverse packaging requirements, from small electronics to retail merchandise. The material composition typically consists of recycled paper fibers, making the corrugated small box an environmentally responsible choice for businesses seeking sustainable packaging alternatives. Applications span across e-commerce fulfillment, retail packaging, gift presentation, sample distribution, and industrial component storage. The corrugated small box excels in situations requiring reliable protection for fragile items, organized inventory management, and professional presentation. Its flat-pack design enables efficient storage before assembly, maximizing warehouse space utilization. The surface of each corrugated small box accepts various printing methods, allowing for custom branding, product information, and handling instructions. Temperature resistance and moisture barriers can be enhanced through specialized coatings, expanding applications to include food products and sensitive materials. Manufacturing flexibility permits custom sizing and design modifications to meet specific client requirements while maintaining the structural benefits inherent in corrugated construction technology.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY