Introduction

In today's increasingly competitive market, good packaging often catches consumers' attention at a glance. Therefore, the surface finish of packaging is key to enhancing its luxurious feel. Hot stamping, UV coating, embossing, and die-cutting are four iconic surface treatments that not only attract consumers' attention but also provide a tactile experience.

Process Introduction

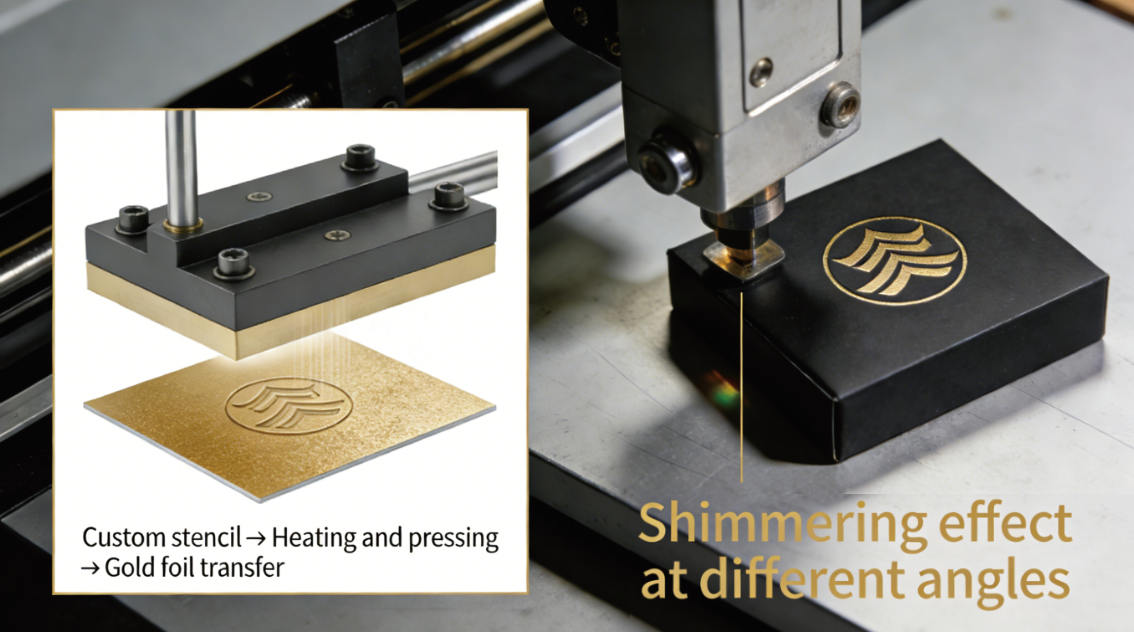

Hot Stamping

Hot stamping is a process that transfers a thin layer of gold foil onto the surface of a material using heat and pressure. It requires a custom-designed hot stamping stencil, which is then pressed onto the gold foil and specific areas to adhere the foil to the material while leaving the rest unchanged. The appeal of hot stamping lies in its ability to create different shimmering effects depending on the viewing angle. It is commonly found in high-end packaging boxes, business cards, etc., and is suitable for highlighting logos and text on materials.

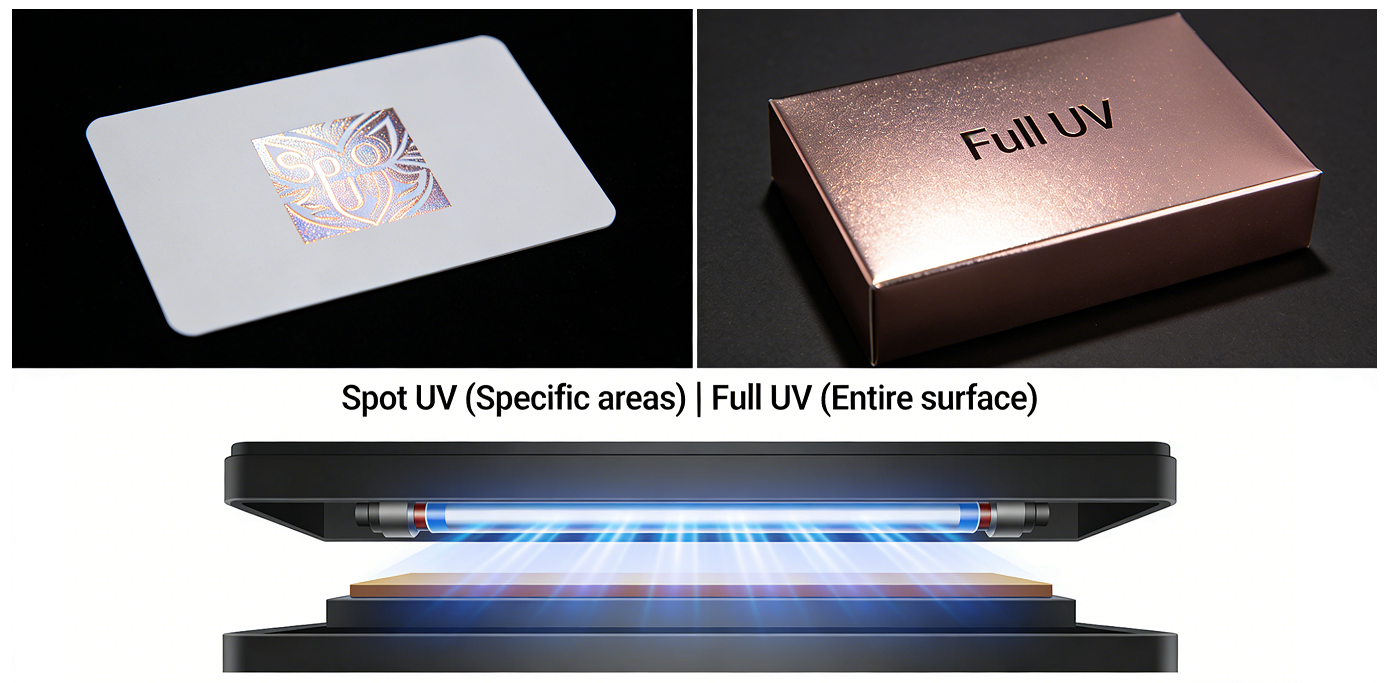

UV Coating

UV coating uses ultraviolet light to cure a transparent liquid coating applied to the material surface, ultimately forming a glossy coating. It is divided into spot UV and full-coverage UV: spot UV applies the coating to a specific area; full-coverage UV applies the coating to the entire surface. Full-coverage UV coating enhances the color saturation of the box while providing some protection, creating a scratch-resistant surface. Spot UV coating creates a unique visual and tactile experience in other areas, resulting in a subtly luxurious feel. It's commonly used in packaging, applied to logos or patterns, giving a glossy and luxurious effect.

Embossing Process

Embossing uses a custom-designed embossing or debossing die to create a raised or recessed effect on the material surface under pressure. Embossing makes raised areas more prominent, attracting attention. It can also be combined with hot stamping for a strong visual impact and a superior visual experience. For other applications, it creates an elegant and understated sense of luxury, ideal for brands seeking a minimalist yet luxurious packaging style.

Die-cutting

Die-cutting is the process of using a custom-made, sharp steel die to cut paper or cardboard. Unlike ordinary rectangular cutting, die-cutting allows for complex contours, perforations, and cutouts, transforming ordinary packaging into highly designed pieces. Therefore, it is widely used in the packaging industry and can be combined with other processes to create exquisite packaging.

Conclusion

Hot stamping, UV coating, embossing, and die-cutting all enable packaging to showcase different levels of luxury, layering effects, and brand creativity. The processes added to packaging not only enhance its texture but also shape the brand and serve as strategic tools. These details also allow consumers to perceive quality and care, generating a positive brand impression.

Contact Jinayon to obtain a one-stop box solution.

FAQ

Which finish best highlights a logo on packaging?

Hot stamping (foil stamping) is ideal for logos, as its metallic sheen draws immediate attention. For added dimension, combine foil with embossing to create a raised, tactile logo effect.

What’s the difference between spot UV and full UV coating?

Spot UV applies a glossy coating only to specific areas (e.g., logos), creating contrast with matte surfaces. Full UV covers the entire package, enhancing color vibrancy and adding scratch resistance.

Can embossing and die-cutting be used together?

Yes. Die-cutting shapes the packaging structure (e.g., custom windows or contours), while embossing adds raised textures to specific areas. Combined, they create multi-sensory, high-impact designs.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY