corrugated cardboard packaging

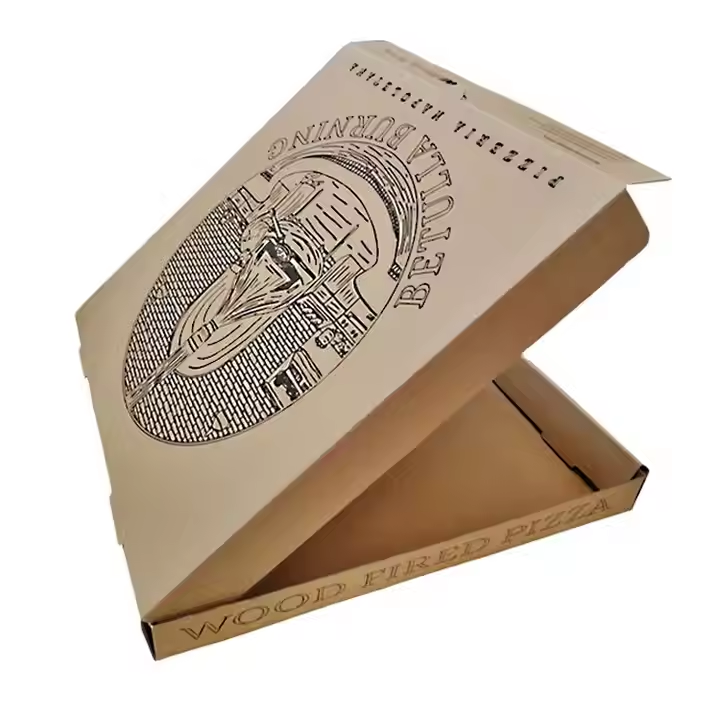

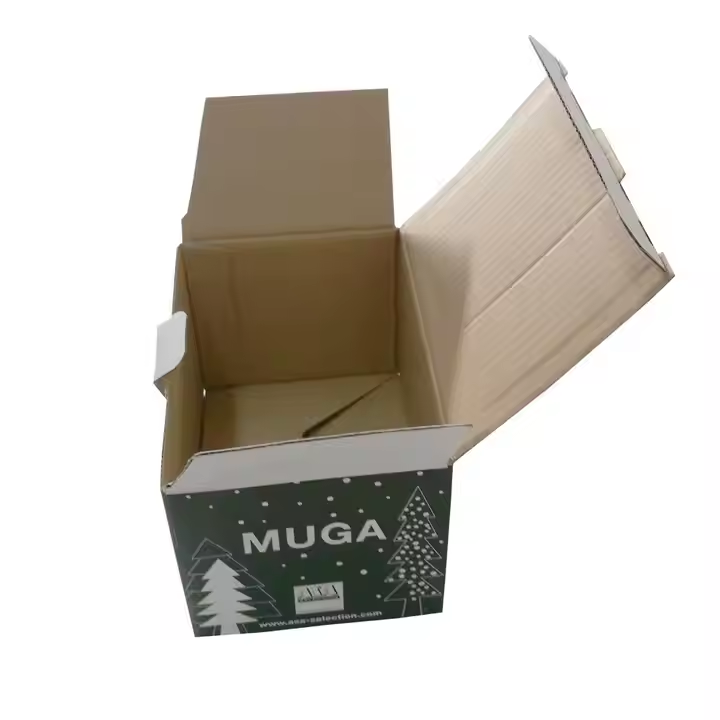

Corrugated cardboard packaging represents one of the most versatile and widely adopted packaging solutions in modern commerce and industry. This innovative packaging material consists of multiple layers, typically featuring a fluted corrugated sheet sandwiched between two flat linerboards, creating a robust yet lightweight structure that delivers exceptional performance across diverse applications. The unique construction of corrugated cardboard packaging provides superior cushioning properties, making it ideal for protecting products during transportation, storage, and handling processes. The primary functions of corrugated cardboard packaging extend beyond simple containment, encompassing product protection, brand communication, cost-effective shipping solutions, and environmental sustainability. The technological features of this packaging system include customizable flute profiles, varying board grades, and advanced printing capabilities that allow businesses to create tailored packaging solutions. Single face, single wall, double wall, and triple wall configurations offer different strength levels to accommodate specific product requirements and shipping demands. The manufacturing process involves precision corrugating machines that bond recycled and virgin fibers using water-based adhesives, resulting in packaging materials that maintain structural integrity while remaining environmentally responsible. Applications for corrugated cardboard packaging span virtually every industry, from e-commerce and retail to automotive, electronics, food and beverage, pharmaceuticals, and industrial components. The material excels in primary packaging for direct product contact, secondary packaging for grouping items, and tertiary packaging for bulk shipments. Advanced coating technologies and barrier treatments enable corrugated cardboard packaging to handle moisture-sensitive products, frozen goods, and items requiring enhanced protection. Digital printing advancements have revolutionized the customization possibilities, allowing businesses to implement variable data printing, personalized messaging, and high-quality graphics that enhance brand visibility and customer engagement throughout the supply chain.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY