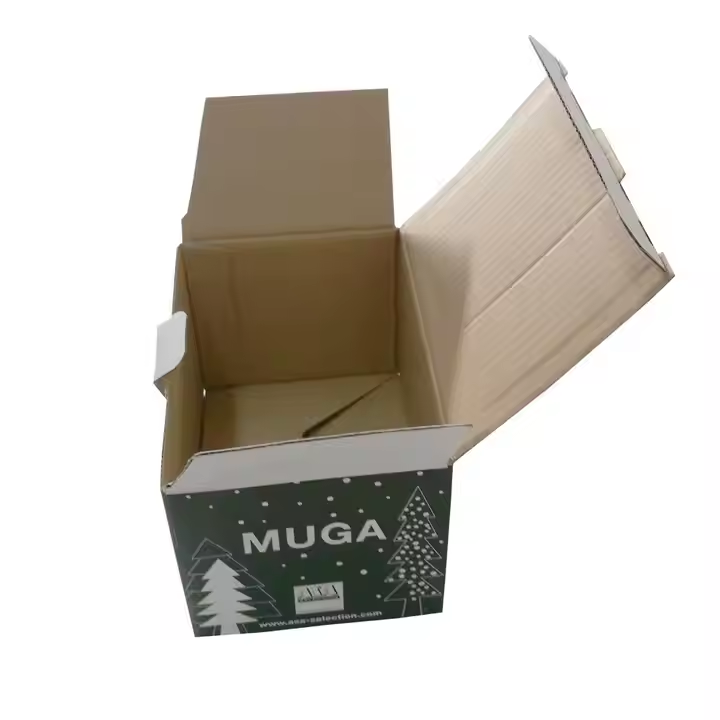

corrugated box for packaging

The corrugated box for packaging represents one of the most versatile and essential packaging solutions in modern commerce and logistics. This innovative packaging system consists of multiple layers of paperboard, featuring a distinctive fluted corrugated medium sandwiched between flat linerboards. The corrugated box for packaging delivers exceptional structural integrity while maintaining lightweight characteristics, making it an ideal choice for shipping, storage, and retail applications across diverse industries. The fundamental design incorporates advanced engineering principles that create superior strength-to-weight ratios through its unique corrugated construction. This packaging solution utilizes recycled materials extensively, positioning the corrugated box for packaging as an environmentally responsible choice for businesses seeking sustainable alternatives. The manufacturing process involves precision machinery that bonds layers of kraft paper using specialized adhesives, creating a robust yet flexible container system. Modern corrugated boxes feature enhanced printing capabilities, allowing for high-quality graphics and branding opportunities that transform packaging into powerful marketing tools. The corrugated box for packaging serves multiple functions including product protection during transportation, efficient storage optimization, and effective brand communication at retail points. Technological innovations have introduced moisture-resistant coatings, anti-static properties, and temperature-resistant treatments that expand the application range of corrugated packaging solutions. These boxes accommodate various product categories from fragile electronics to heavy industrial components, demonstrating remarkable adaptability. The standardized sizing options ensure compatibility with automated packaging equipment, streamlining operational efficiency for manufacturers and distributors. The corrugated box for packaging continues evolving through technological advancements, incorporating smart packaging features, improved barrier properties, and enhanced sustainability credentials that meet contemporary business requirements while supporting environmental conservation efforts.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY