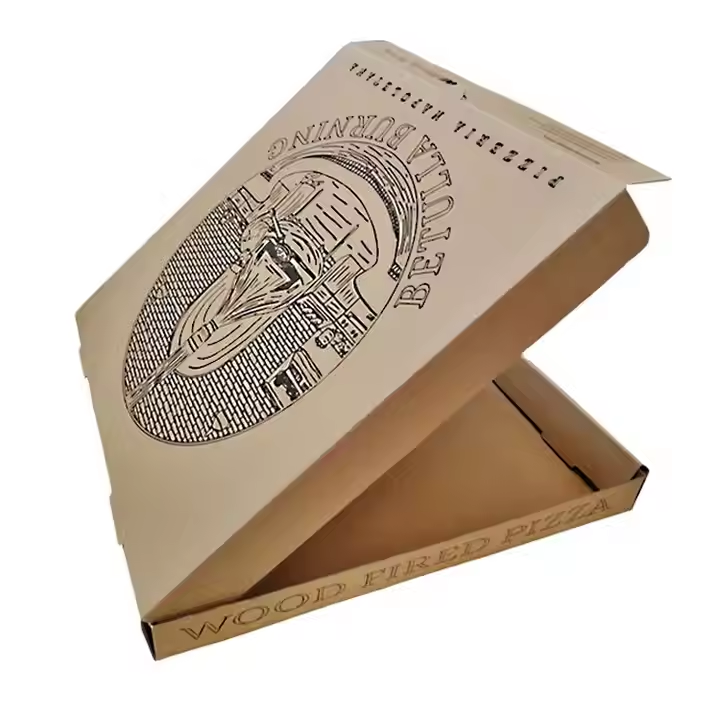

double corrugated cardboard

Double corrugated cardboard represents a sophisticated packaging solution that combines two layers of corrugated fluting between three layers of flat cardboard sheets, creating an exceptionally robust and versatile material. This advanced construction method produces packaging materials that significantly outperform traditional single-wall corrugated options in terms of strength, durability, and protective capabilities. The manufacturing process involves bonding two separate corrugated layers together, resulting in a thick, cushioned structure that provides superior impact resistance and load-bearing capacity. The technological features of double corrugated cardboard include enhanced compression strength, improved puncture resistance, and excellent insulation properties that protect contents from temperature fluctuations and moisture damage. This multi-layered construction creates air pockets that act as natural shock absorbers, making it ideal for shipping fragile or valuable items across long distances. The material maintains its structural integrity even under significant weight loads, making it suitable for heavy-duty applications. Applications for double corrugated cardboard span numerous industries, including electronics packaging where sensitive components require maximum protection, furniture shipping where large items need structural support, and industrial goods transportation where durability is paramount. The automotive industry frequently utilizes this material for parts packaging, while e-commerce businesses rely on double corrugated cardboard for secure product delivery. Its versatility extends to custom packaging solutions, point-of-sale displays, and protective inserts for delicate merchandise. The material can be easily customized with printing, die-cutting, and specialized coatings to meet specific branding and functional requirements. Environmental considerations make double corrugated cardboard an attractive choice, as it maintains recyclability while providing enhanced performance characteristics that reduce the need for additional protective materials.

EN

EN

AR

AR

BG

BG

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

IW

IW

TH

TH

MS

MS

HY

HY